Core Working Principle of LED Display Screens

Electroluminescence: How LEDs Convert Electricity into Light

LED displays work by using electroluminescence, basically when semiconductor materials give off light as electricity passes through them. Unlike those old LCD screens that need backlights, every single LED produces its own illumination right there. Because of this direct conversion from electricity to light, these displays can get really bright, sometimes hitting around 10,000 nits for outdoor use, and they actually use about half the power compared to older display tech. Since there are no liquid crystals or those fancy optical filters involved, LED screens tend to be thinner, offer better viewing angles from different positions, and generally have much sharper contrast between dark and light areas.

Pixel Architecture and RGB Subpixel Control for Full-Color Imaging

Each pixel consists of three microscopic subpixels—red, green, and blue—each driven independently. By modulating subpixel intensity via pulse-width modulation (PWM), the display reproduces up to 16.7 million colors with high fidelity. Key structural components include:

| Component | Function | Impact |

|---|---|---|

| LED Chips | Emit colored light | Determines color accuracy and luminance uniformity |

| Driver ICs | Regulate voltage and current per subpixel | Ensures brightness consistency across the panel |

| PCB Layout | Routes signals between subpixels and drivers | Minimizes crosstalk and color bleeding |

High-density configurations—such as P1.2mm pitch—achieve native 4K resolution on large-format screens through precise pixel clustering and advanced mapping algorithms.

Scanning Methods: Static vs. Multiplexed Driving for Brightness and Refresh Stability

When static driving is used, all those LEDs light up at once, which gives maximum brightness and no annoying flicker. That makes them great for those big outdoor signs we see in bright daylight. But there's a catch. This approach eats up about 25% more electricity compared to other methods, so manufacturers need to think seriously about how they manage heat buildup. On the flip side, multiplexed driving works differently by turning on LED rows one after another. This cuts down both power consumption and heat production, plus it can handle incredibly high refresh rates reaching as much as 7680Hz. Of course, getting this right takes special timing equipment to make sure each row lights up just when needed. Without proper synchronization, viewers might notice strange visual effects especially when watching fast moving scenes on these displays.

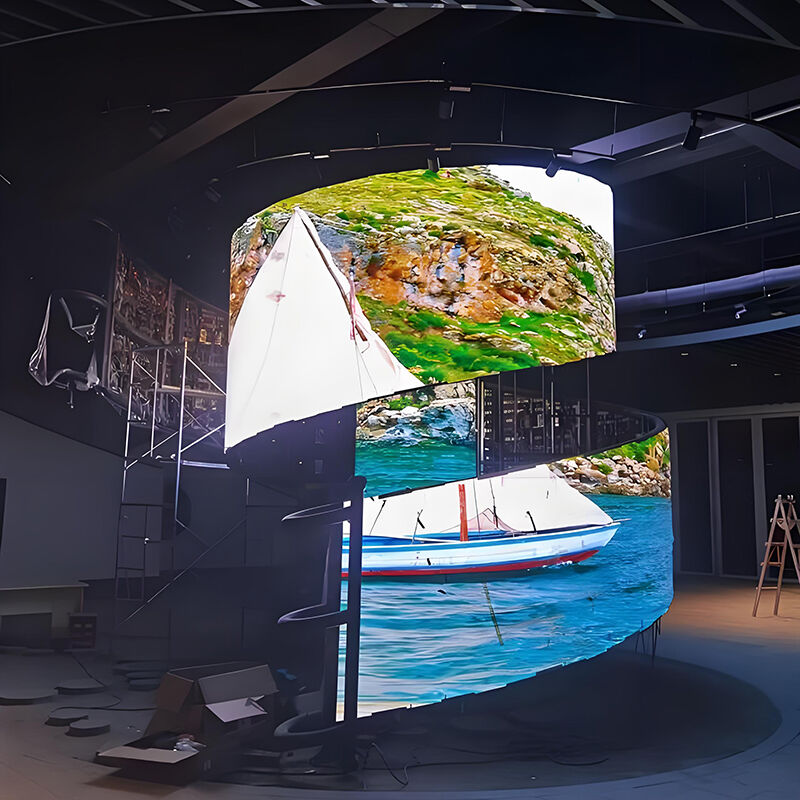

What Makes an LED Display Screen Flexible?

Flexible Substrates: From Polyimide Films to Embedded Copper Mesh Interconnects

The real flexibility starts with the substrate, which serves as the base material taking the place of traditional rigid options like glass or FR-4 PCBs. Most manufacturers turn to polyimide films for this role because they can handle extreme heat conditions during production processes, often surviving temperatures above 400 degrees Celsius. These incredibly thin polymer materials allow for tight bends with radius measurements below 10 millimeters without developing tiny cracks. Some newer versions actually include copper mesh wiring systems that maintain signal integrity even after thousands of flex cycles something regular printed circuit boards just cant match. When paired with protective rubber coatings, these flexible structures meet IP65 standards against water and dust ingress, making them ideal for installation on curved surfaces, rounded pillars, and those complex architectural features that architects love but engineers sometimes dread.

Micro-LED Transfer and Bend-Tolerant Circuit Design

Real flexibility at the component level requires some serious innovation work. The tiny Micro-LED chips, which measure under 100 micrometers, get placed on Flexible Printed Circuit Boards through methods like laser assistance or those special elastomeric stamps that help reduce stress during placement. For the circuitry itself, engineers have moved away from traditional straight line designs to something much more adaptable: stretchable serpentine patterns or even fractal shaped traces. These layouts spread out mechanical strain across the board rather than concentrating it in one spot. Instead of relying on standard solder joints, conductive adhesives are now used because they can handle vibrations and twisting forces better. What makes this whole system so impressive is how durable it actually is. We're talking about displays that can withstand well over 100 thousand bending cycles with a radius of around 25 millimeters without any pixels failing. And there's more too. Those distributed micro heatsinks do their job managing heat buildup when things get bent or twisted, allowing for consistent brightness levels right up to 5,000 nits and wide viewing angles approaching 140 degrees even when the display isn't flat anymore.

Flexible LED Display Cost Analysis: Drivers, Tiers, and Value Optimization

Cost Breakdown: Premium Factors Including Material, Yield, and Calibration Complexity

Flexible LED displays carry a premium due to specialized materials, tighter tolerances, and added process complexity. Primary cost drivers include:

- Advanced substrates, such as polyimide films with embedded copper mesh, increasing material costs by 25–40% versus standard rigid PCBs.

- Micro-LED transfer precision, where sub-0.1mm placement accuracy requirements contribute to 15–30% yield loss in high-density configurations.

- Calibration complexity, as curvature-induced gamma shifts and non-uniform viewing angles require ~20% more labor-intensive color and brightness calibration—especially for displays targeting ¥5,000 nits.

| Cost Factor | Impact Range | Technical Consideration |

|---|---|---|

| Material quality | 40–60% of total | Polyimide/copper vs. standard PCB |

| Manufacturing yield | ±15% variance | Sensitivity to <0.1mm placement errors |

| Color calibration | +20% labor time | Curvature-specific gamma and white-point correction |

ROI Strategies: Modular Installation, Reusability, and Total Cost of Ownership Savings

The real money comes from smart design decisions that keep equipment useful long after first setup. Take modular panels for instance these can be reused again and again across different marketing campaigns which cuts down on replacement expenses sometimes as much as half. The energy aspect adds another layer of savings too. Flexible LED technology actually uses around thirty percent less electricity compared to standard options and lasts about 100 thousand hours before needing replacement. Standardized mounting parts make life easier during installations cutting labor time by roughly 35 percent. This also means faster transitions between venues and better support when upgrading later on. Looking at everything together energy consumption maintenance needs reconfiguration possibilities and overall lifespan flexible LED screens typically end up costing less over time compared to traditional rigid displays especially where spaces need frequent changes or multiple purposes.

FAQ on LED Display Screens

What is the main advantage of using LEDs for displays?

LEDs offer direct conversion from electricity to light, leading to higher brightness and energy efficiency compared to older display technologies. They are thinner, provide better viewing angles, and have sharper contrast.

Why do flexible LED displays cost more than standard ones?

Flexible LED displays cost more due to specialized materials like polyimide films, precise manufacturing processes, and additional labor for calibration, which increases their overall production cost.

How do multiplexed driving methods reduce power consumption?

Multiplexed driving methods turn on LED rows sequentially, lowering power usage and heat production, while static driving lights up all LEDs simultaneously, consuming more electricity.

What makes flexible LED displays durable?

Durability in flexible LED displays comes from innovative designs, such as stretchable circuit patterns, conductive adhesives that handle mechanical strains, and distributed micro heatsinks for effective heat management, allowing displays to endure over 100,000 bending cycles.