Why LED Display Dominates: Unmatched Brightness, Lifespan, and Efficiency

Brightness supremacy: 5,000–10,000 nits for outdoor visibility vs. LCD/OLED limitations

LED screens can reach brightness levels between 5,000 to 10,000 nits, making them clearly visible even under bright sun conditions. Compared to other technologies, this level of brightness leaves LCDs in the dust since they typically lose about 30% of their brightness due to those pesky polarizers and backlights. OLED displays face similar issues too, as their maximum brightness gets capped because of limitations in the organic materials used. The real advantage comes from how LEDs work fundamentally different. They produce light right at the source, so the brightness stays steady no matter what environment they're placed in. No annoying glare or washed out images when sunlight hits them head on. For anyone needing displays that work well outdoors or in brightly lit spaces, LED technology remains the most practical solution available today.

100,000+ hour lifespan with zero burn-in—outperforming OLED and avoiding LCD backlight decay

Most LED displays last well beyond 100,000 hours before showing signs of wear, which works out to around 11 years if running nonstop day after day. They don't experience the same issues as OLED screens that get stuck images when displaying static content for too long, nor do they have the backlight problems common with traditional LCD monitors where those old CCFL lights just fade away over time. The solid state design of LEDs means these screens can handle constant operation without breaking down. Businesses save money in the long run since replacements happen far less often compared to other technologies. For places needing reliable screen performance without interruption, such as massive outdoor billboards or security monitoring stations, LEDs have become the go to choice because they simply work better under pressure.

Energy efficiency and thermal resilience in continuous high-brightness operation

LED screens today can cut energy use by around 40% compared to similar LCD or OLED setups and still maintain bright visuals. The way these displays manage heat is pretty impressive too. Most have aluminum heat sinks built right in, along with passive air channels that help dissipate warmth. Some models even come equipped with quiet cooling fans when extra help is needed. This whole system keeps everything running smoothly across a wide temperature range, typically from as cold as minus 20 degrees Celsius all the way up to 50 degrees. What does this mean for users? Less overheating issues and parts that last about 30% longer on average. That's good news for anyone concerned about environmental impact and wanting to save money over time. Actual case studies show businesses saving well over fifteen thousand dollars each year just on electricity bills alone, especially at those big outdoor digital billboards that need to stay lit day and night.

LED Display Types Compared: From SMD to MicroLED

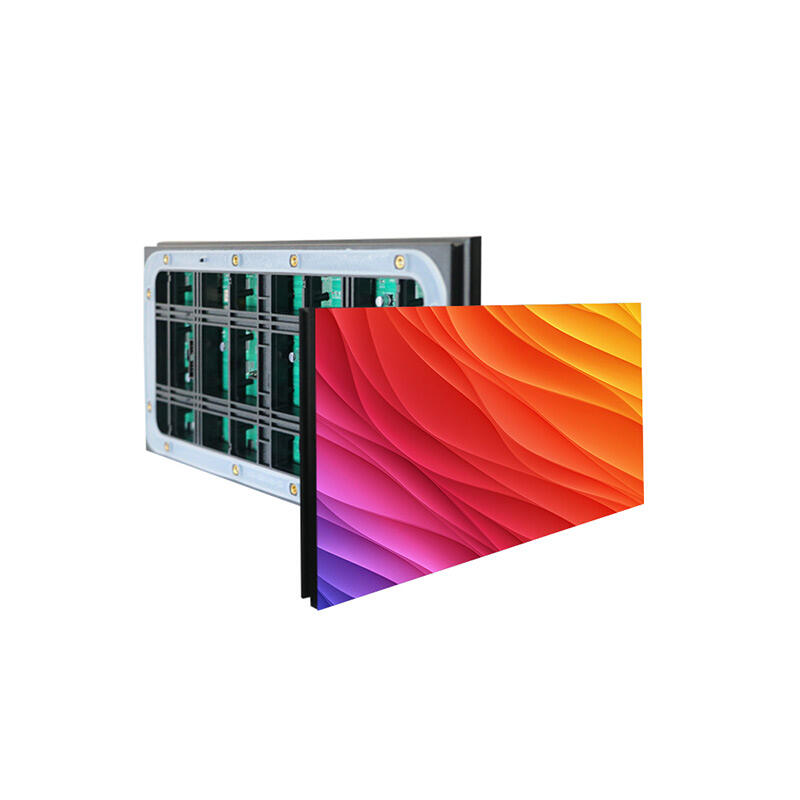

SMD LED: The versatile standard for indoor/outdoor signage (P1.2–P10, balance of resolution and cost)

SMD LED tech combines red, green, and blue chips all in one small package. This allows for pixel pitches ranging from really fine P1.2 right up to the sturdier P10 format. The modular setup makes it easy to scale things up or down depending on what's needed. We're talking about everything from those super detailed displays in corporate buildings to budget friendly outdoor ads. These panels offer pretty good viewing angles too, around 140 degrees actually, and can handle outdoor brightness levels as high as 8,000 nits while still keeping colors looking sharp and true. Plus maintenance isn't so bad either since modules can be swapped out hot. Most businesses have gone with this SMD approach for their signs because it just works reliably day after day.

COB & GOB LED: Enhanced reliability for rental, stage, and harsh environments (dust/moisture resistance, pixel protection)

COB (Chip-on-Board) and GOB (Glue-on-Board) tech places LED chips right under a protective epoxy coating instead of leaving solder points and those delicate surface mount connections exposed to damage. The whole package gets sealed tight, giving it IP68 waterproof rating and making it about three times tougher against impacts compared to regular SMD displays we see everywhere else. For environments where things get shaken up constantly or temperatures swing wildly between extremes like concert stages that travel across countries, cold storage facilities, or outdoor music events in hot climates, these COB and GOB solutions cut down on pixel failures by around 60%. They keep working reliably even when temps drop below freezing at -30 degrees Celsius all the way up to scorching 85 degrees Celsius without missing a beat.

Mini LED vs. MicroLED: Hybrid backlighting vs. true emissive scalability—readiness, cost, and application fit

Mini LED isn't actually a display technology per se, it's more accurately described as an advanced form of LCD backlighting. The tech works by packing thousands of tiny LEDs measuring less than 1mm across, creating local dimming zones that can boost contrast ratios all the way to 1 million to 1. This makes them particularly well suited for those premium control room setups where folks still prefer the traditional LCD form factor. True MicroLED takes things in a completely different direction though. Instead of relying on backlights or filters, these displays use self-emitting microscopic LEDs (under 100 micrometers) placed directly onto substrate materials. There's no need for any of those extra layers found in conventional displays. What does this mean? Better brightness consistency across the screen, expanded color range, and roughly 30 percent less power usage compared to OLED panels. But there's a catch. Manufacturing yields remain problematic and costs are still prohibitively high. At around $15,000 per square meter, most MicroLED installations end up being limited to top tier command center applications. On the other hand, Mini LED solutions ready for production today typically start at about $1,200 per square meter. For businesses looking at high end visualization needs, this represents a much more accessible option with tangible return on investment within months rather than years.

Key Selection Criteria for LED Display Deployment

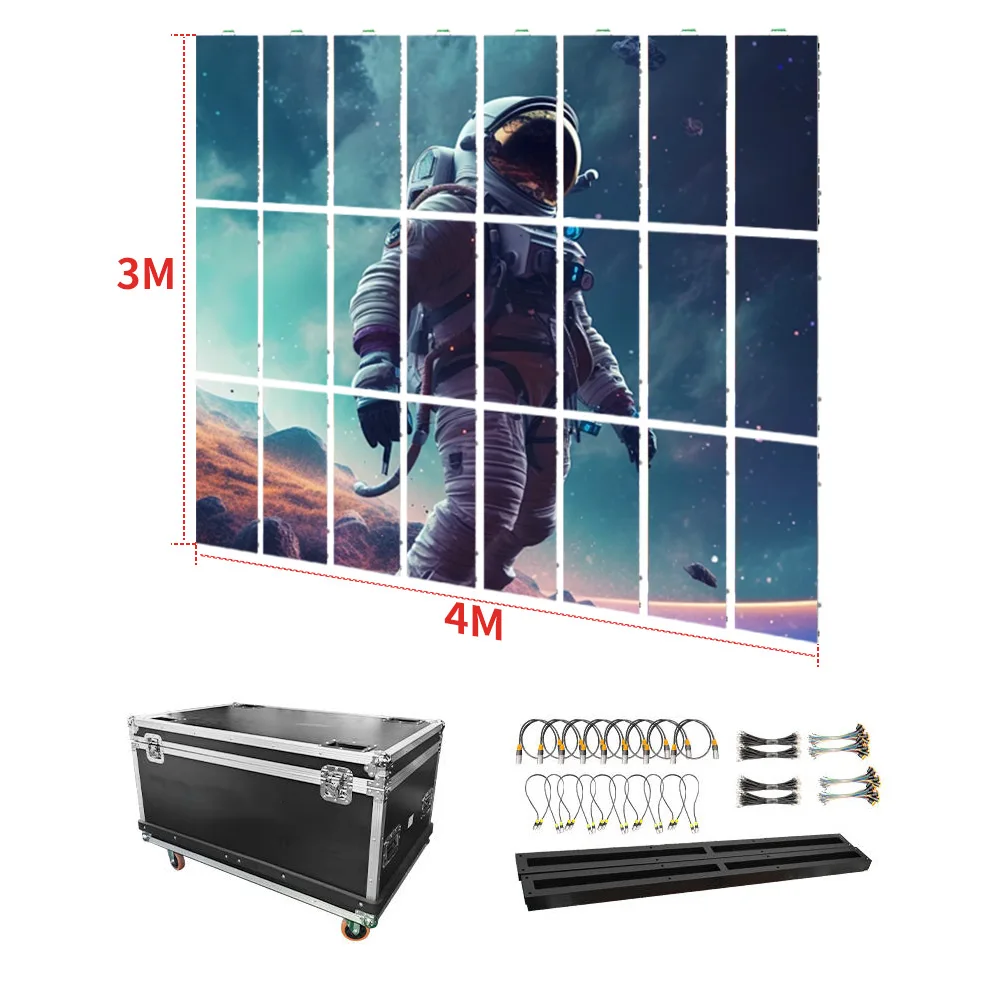

Pixel pitch and viewing distance: Calculating optimal clarity (e.g., P2.5 for 3m, P10 for 15m)

The space between those little LED clusters on a screen, which we measure in millimeters, basically determines how clear the image looks and how close someone can stand to see it properly. P2.5 displays give good clarity when viewed from around 2.5 meters away, so they work great in places like meeting rooms and stores inside buildings. For outside ads, most people go with P10 screens since they stay readable even from 10 to maybe 15 meters back. Sure, there's this handy formula where you multiply the pitch by 1,000 to get a rough idea of minimum viewing distance, but real life isn't always so straightforward. Content matters too - text needs closer viewing than videos generally do. Lighting conditions and where exactly the screen gets mounted play roles as well. These days, the finer pitch LEDs are showing up everywhere indoors, but for big outdoor signs where things need to be seen from far away, the bigger pixel gaps still make practical sense for most businesses.

Brightness and environmental rating: Why IP65 + thermal management spec-sheet nits alone

The numbers on paper don't tell the whole story when it comes to outdoor LED displays. Sure, we're talking about at least 5,000 nits for visibility, but what really matters is whether the display can handle the elements. The enclosure needs to be IP65 rated, meaning it should keep dust out completely and withstand water jets from any direction. And let's not forget about managing all that heat generated by such bright screens. Without proper thermal control, these LEDs lose their brightness faster and are more likely to fail altogether. Some models come with passive heat sinks while others have fans or other active cooling systems, which can actually make them last around 30% longer before needing replacement. Looking only at those impressive nit ratings misses the bigger picture though. Moisture gets everywhere, UV rays take their toll, and temperature changes day after day wear down even the best equipment over time. That's why smart installers focus on getting displays with solid IP65 protection and reliable thermal management first. These features ensure clear images stay visible, reduce maintenance headaches, and ultimately protect the investment especially when deployed in harsh weather conditions where failures would be most inconvenient.

LED Display Use-Case Matching: Real-World Application Guidance

Outdoor advertising: High-brightness SMD or COB with anti-glare, solar-ready drivers, and UV-stable cabinets

When it comes to billboards and outdoor ads, they need to stand up to whatever Mother Nature throws at them just as much as they need to catch people's eyes. The best ones use SMD and COB technology that can hit around 8,000 nits of brightness so messages stay visible even on sunny days. Their cabinets are made from special aluminum treated to withstand UV rays without fading or getting warped after years in direct sunlight. There's also solar optimized circuitry that keeps power steady when temperatures spike during those brutal afternoon hours, plus coatings that cut down glare from different angles. All these smart design decisions work together to make these displays last about 40 percent longer than regular ones that weren't built for tough conditions.

Stage & XR volumes: GOB-protected fine-pitch LED for impact resistance, seamless splicing, and color consistency

In live production settings, the displays need to withstand all sorts of abuse during shipping, setup, and quick changes without messing up the image quality. GOB encapsulation on those sub 1.5mm pitch LEDs gives them the toughness needed when they get handled constantly, plus lets crews create those smooth curved screens so important for XR stage work. When panels come factory calibrated, they hit Delta E below 1.5 throughout the whole display area, which means colors stay spot on even when lights change or cameras roll. The numbers back this up too - according to what top production companies reported in 2023, these setups maintain over 98 percent color consistency through hectic scene switches. Makes sense why so many studios rely on them now for creating those realistic, camera friendly spaces.

FAQ

What are nits in LED displays?

Nits are a unit of measurement for brightness. LED displays can achieve between 5,000 to 10,000 nits, making them highly visible even under bright sunlight.

How long do LED displays last?

LED displays typically have a lifespan exceeding 100,000 hours due to their solid state design, which is approximately 11 years if used continuously.

How do LED displays save energy compared to LCD or OLED?

LED displays use around 40% less energy than LCD or OLED screens due to efficient heat management systems that include aluminum heat sinks and passive air channels.

Why is IP65 rating important for LED displays?

An IP65 rating ensures that LED displays are dust-tight and can resist water jets from any direction, making them suitable for outdoor conditions.