What Is Mini LED Display Technology and How Does It Work?

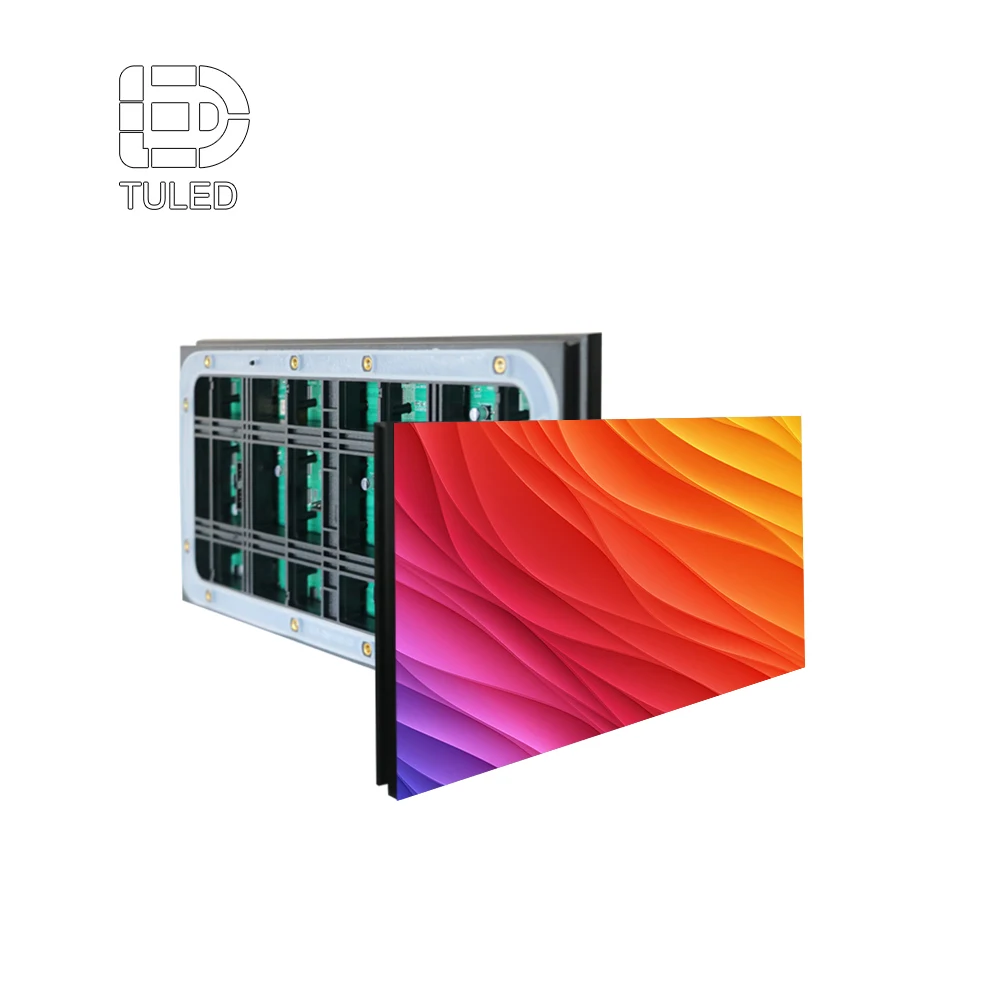

Definition and Structure of Mini LED Displays

Mini LED tech works by packing thousands of tiny LEDs into LCD screens for better backlighting. These little guys measure around 100 to 200 microns each, which is about 80% smaller than regular LEDs. The smaller size lets manufacturers have much better control over how bright different parts of the screen get. Take a standard 65 inch mini LED television for example. Inside there's somewhere between 5,000 and 10,000 of these miniature lights organized in grids covering over 1,000 separate dimming areas. This setup means the TV can adjust brightness levels locally rather than having everything on or off at once, resulting in much sharper picture quality overall.

How Mini LED Improves Brightness, Contrast, and HDR Performance Over Traditional LCDs

Mini LED technology takes things to another level by boosting dimming zones from roughly 100 found in regular LED-LCD screens all the way up to over 5,000 in premium models. This massive increase leads to contrast ratios that are about three times better than standard displays. What makes this possible? Advanced pulse width modulation allows each individual zone to adjust brightness levels as low as 0.0001 nits while still hitting those impressive peak brightness levels of around 4,000 nits when needed. The result is stunning HDR content with truly deep black areas next to bright highlights. Color reproduction gets pretty amazing too, covering about 98% of the DCI-P3 color space used in movie theaters. And there's one big plus for everyday viewing: it almost completely eliminates that annoying halo effect we see around bright objects on edge-lit LCD screens.

Mini LED as a Bridge Technology Between Conventional LED and MicroLED

MicroLED technology definitely delivers outstanding picture quality, but let's face it - the price tag is still way too steep for most consumers, often going over $10k for bigger screens. That's where mini LED comes in handy. These panels give around 90% of the contrast advantages we get from microLED, yet they cost much less to produce. The reason? Mini LED manufacturers have found clever ways to merge traditional LCD production methods with some pretty impressive backlighting tech that gets close to OLED quality. For now, this approach works well as a stopgap measure while the industry figures out how to bring down those astronomical microLED prices and make them accessible to regular folks.

Key Applications of Mini LED in Premium TVs, Monitors, and Tablets

Manufacturers now deploy mini LED in flagship products such as gaming monitors (with sustained brightness up to 1,200 nits), 12.9" tablets featuring 2,600 local dimming zones, and 8K TVs. The market for mini LED gaming displays has grown 240% year-over-year, driven by demand for sub-10ms response times and cinema-grade HDR performance.

What Is Micro LED Display Technology and What Makes It Revolutionary?

Definition and architecture of micro LED displays

Micro LED tech, often called µLED, works by using tiny light emitting diodes that measure under 100 microns wide roughly the same as a tenth of a human hair strand as actual light sources for each pixel. What sets it apart from regular LCD screens or even mini LED setups is that there's no need for a separate backlight source since every single pixel creates its own illumination. The result? Deep blacks on screen without any light leakage, plus panels can be joined together without visible borders making huge display walls possible. Plus, because these components are made from inorganic substances rather than organic ones, they tend to last longer and don't degrade as quickly over time compared to other display technologies currently available.

Self-emissive pixels: How microLED differs from LCD and mini LED

MicroLED pixels generate their own light, which means no backlights, color filters or those liquid crystal layers that are standard in traditional LCD and mini LED screens. The self-emitting nature allows these displays to react almost instantly, with response times below 1 millisecond, while covering nearly all of the DCI-P3 color spectrum at 99%. What makes microLED really stand out is its ability to control each pixel's brightness individually. This gives it what some call "infinite" contrast ratios, something that even top tier mini LED tech can't match since those rely on dimming areas rather than individual pixel control.

Superior efficiency, brightness, and lifespan of microLED technology

MicroLED displays can hit brightness levels over 3000 nits, which is actually twice as bright as OLED panels, and they do this while using about 40 percent less power than regular LCD screens. The reason MicroLED doesn't suffer from burn-in problems like OLED does lies in its inorganic materials, something that also gives these displays an impressive life expectancy of around 100 thousand hours. When tested over time, MicroLED retains roughly 95% of its initial brightness even after running for 10 thousand hours straight, whereas OLED typically drops down to only 72% brightness under the same testing conditions. These figures highlight why many experts believe MicroLED represents a significant step forward in display technology.

Current use cases in large-format displays and luxury devices

We're starting to see these tech marvels show up in places like fancy home theaters and big corporate spaces, where those 8K video walls stay crystal clear no matter how close someone gets to them. The really expensive smartwatches are getting in on the action too, using this microLED stuff to create super bright displays that can be read outside under direct sunlight while still lasting longer between charges. Sure, right now the price tag keeps most people from buying one, but experts think things might change pretty fast. Some folks in the industry predict costs could drop around 30% each year once production ramps up enough to meet demand.

Mini LED vs Micro LED: Key Differences in Performance and Design

Size, Pixel Density, and Structural Differences Between Mini and Micro LEDs

These two tech options stand apart when it comes to their basic size and how they work. Mini LEDs measure between about 100 to 300 microns and basically act as upgraded backlights sitting behind those LCD panels we all know. Micro LEDs? They're even tinier stuff, under 100 microns actually, and each one glows on its own without needing anything else. Looking at numbers from Omdia's latest report on displays for 2025, the tiny size gives microLED some serious punch with pixel density hitting above 10,000 PPI. That beats what mini LEDs can do which tops out around 2,000 PPI max. When it gets down to actual construction, mini LEDs need those liquid crystal layers plus complicated software to control lighting effects. But microLED just shines light right out from the pixels themselves, so there's no problem with light bleeding through from behind. Still, manufacturers run into similar headaches making either option work at scale because transferring all those tiny components remains tricky business in real world factories.

Performance Comparison: Contrast, Response Time, and Energy Efficiency

MicroLED technology stands out because it offers essentially unlimited contrast ratios and incredibly fast response times at just 0.1 milliseconds. This beats what mini LED can do, which manages about 1 million to 1 contrast ratio and response times between 2 and 4 milliseconds. Mini LED does save around 40% on power consumption when compared to regular LED LCD screens, but microLED takes things even further by lighting up each individual pixel separately. The really high end versions of microLED can push brightness all the way to 10,000 nits, although most consumer products these days max out at around 4,000 nits since that works best for everyday viewing conditions without causing eye strain or washout effects.

Is MicroLED Overhyped? Evaluating Real-World Advantages Over Mini LED

MicroLED technology sounds great on paper but runs into serious practical problems when trying to manufacture it at scale. The production yield rates for those tiny components under 100 microns hover around 50 percent max, while mini LED manufacturing hits over 85%. That makes a huge difference in cost. Take that new 136 inch microLED television sitting at $150k versus the mini LED version available for just $2,500. Most consumers simply can't afford such a gap. Industry insiders agree that unless there are major improvements in how these components get transferred during manufacturing, we won't see microLED becoming mainstream anytime soon. Experts predict it will stay a specialty product through 2030 at minimum.

How Do Mini LED and Micro LED Compare to OLED and LCD Displays?

Mini LED vs OLED vs LCD: Brightness, burn-in risk, and color accuracy

The brightness difference between Mini LED and OLED is pretty significant actually. Mini LED can hit around 1500 nits compared to OLED's 500 nits, so it works much better in well lit spaces. One big advantage over OLED is that Mini LED doesn't suffer from screen burn issues when showing static images for long periods. OLED panels have this problem where logos or UI elements can leave ghostly marks on the display. That said, OLED still holds its own when it comes to colors and contrast ratios. With about 98% DCI-P3 coverage and those individual pixel lights, OLED displays tend to look deeper and more realistic overall, especially in dark environments.

Why microLED outperforms OLED and LCD in theory—but not yet in market share

MicroLED technology brings together the brilliant brightness we see in LED backlit displays with those deep black levels similar to OLED screens. Theoretically speaking, this combination should cut power consumption by about 40% compared to traditional LCDs. But here's the catch: MicroLED only makes up less than 0.1% of the entire display market right now because manufacturing costs are roughly 12 times what they are for OLED production. Looking at current factory output rates, manufacturers can only produce around 65% working 4K microLED panels, while OLED factories hit much better rates at around 92%. These low yield numbers mean most people won't find these displays anywhere except in special commercial settings or on those massive ultra HD screens we sometimes see in public spaces.

Industry challenges: Why OLED still dominates despite microLED’s superior specs

The OLED technology holds around 68% of the high-end television market these days, especially when we're talking about TVs costing more than two grand. This dominance comes from well-established manufacturing processes and those super thin panels that are so important for phones and other gadgets that need to be carried around. Now, microLED does have something going for it though - it lasts about 100,000 hours, which is roughly three times longer than what OLED offers. But let's face it, nobody wants to spend forty grand on an 110 inch screen for their living room. That kind of money keeps microLED stuck mainly in business settings right now. Most experts think it will take until somewhere between 2028 and 2030 before microLED becomes as affordable as OLED. Until then, there's still plenty of time for mini LED technology to catch up both in terms of how good it looks and how much people are willing to pay for it.

Challenges and Future Outlook for Mini LED and Micro LED Adoption

Manufacturing Complexity and Cost Barriers for MicroLED Scalability

To make one 4K microLED panel, manufacturers have to put together around 24.8 million tiny self emitting LEDs. This intensive process makes production costs anywhere from three to five times what it costs to produce OLED panels. Getting those microscopic components onto the panel surface requires state of the art robotic equipment capable of picking up and placing each LED precisely. Even with all this technology, the success rate remains pretty low at under 70% for panels larger than 100 inches across. Because of these challenges, microLED tech stays mostly confined to premium home theater setups and expensive commercial installations where budgets can absorb such high prices.

Current Limitations of Mini LED in Competing with OLED in Thinness and Blacks

Mini LED tech does come with around 1,000 local dimming zones which helps boost contrast levels, but it still falls short compared to what OLED can do with individual pixel control. The problem comes from how mini LED works with backlights instead of emitting its own light. This means black areas tend to look grayish in really dark scenes, especially when light leaks through from neighboring zones, resulting in those annoying halo effects we all know too well. Another downside? These panels end up being about 20 to maybe even 30 percent thicker than their OLED counterparts. That thickness makes them harder to fit into super slim gadgets such as foldable smartphones or those ultra thin laptops everyone wants these days. But don't count mini LED out just yet. Industry forecasts suggest that by 2025, we'll probably see something like 30% or so of high end televisions using this technology.

The Road Ahead: When Will MicroLED Become Mainstream in Consumer Electronics?

Industry experts predict microLED manufacturing costs could fall around 40 percent by 2027, which might finally make these displays viable for smartwatches and car dashboards. But getting them into mainstream TVs remains tricky because of problems transferring the tiny LEDs during assembly. Right now factories can only handle about 10 million LEDs each hour, but they need to boost that number twenty times over just to keep up with what people want worldwide. For now at least, mini LED technology stays king in the premium market segment. These displays strike a good balance between picture quality and how easy they are to mass produce, making them popular choice for everything from computer screens to tablet devices and even virtual reality goggles.

FAQs

What is the main difference between Mini LED and Micro LED?

Mini LED acts as an upgraded backlight for LCDs, while Micro LED is self-emissive, with each pixel producing its own light.

Why are Micro LED displays more expensive than Mini LED?

Micro LED involves complex manufacturing processes with lower yield rates, making them significantly more costly to produce than Mini LED displays.

Are Mini LED TVs better than traditional LCDs?

Yes, Mini LED TVs offer enhanced brightness, contrast, and HDR performance, making them superior to traditional LCDs.

When will Micro LED become more affordable?

Experts predict that Micro LED costs could drop significantly by 2027, making them more accessible to consumers.

Can Mini LED displays compete with OLED in terms of color accuracy and contrast?

While Mini LED displays have improved contrast and color reproduction, OLEDs still provide superior color accuracy and contrast with individual pixel control.