What Is a Flexible LED Display? Core Technology and Design Principles

How flexible LED displays work: Bendable substrates, micro-LED integration, and dynamic mounting

The new wave of flexible LED displays swaps out traditional glass for bendable polyimide films, which lets them twist and turn without losing their functionality. These tiny micro-LED chips, measuring less than 100 microns across, get stuck right onto flexible PCBs through something called surface mount tech. What's interesting is how they maintain all their electrical connections even when bent around corners. The mounting system itself is pretty clever too. It combines adjustable tension frames with magnetic connectors that basically take the hit whenever there's stress on those curved surfaces. According to some industry reports from last year, these displays can actually curve down to about 500mm radius while still shining bright enough at over 5,000 nits. Pretty impressive stuff if you ask me.

Key structural innovations enabling curvature, lightweighting, and seamless tiling

Three foundational innovations overcome traditional display constraints:

- Laminate-Free Designs: Removing glass layers cuts weight by 60% versus conventional LED displays—enabling ceiling, column, and suspended installations.

- Honeycomb Backplanes: Interlocking hexagonal PCB segments allow ±15° directional adjustment for compound curves.

- Pixel-Shift Compensation: Onboard processors detect panel orientation and dynamically recalibrate color across tiles, eliminating visible seams. Together, these features support seamless tiling on spherical, cylindrical, and undulating surfaces—with submillimeter gap tolerances.

COB LED Display Explained: Packaging Advantages and Manufacturing Differentiation

COB vs SMD: Chip-on-Board packaging process and its impact on protection and thermal management

COB (Chip-on-Board) technology mounts bare LED chips directly onto a PCB and encapsulates them in protective resin—bypassing the multi-step SMD process of pre-packaging individual diodes and soldering discrete components. This integration delivers three key advantages:

- Enhanced Protection: Resin encapsulation achieves IP54+ resistance to dust, moisture, and impact—critical for harsh or high-traffic environments.

- Superior Thermal Management: Direct bonding to metal-core PCBs improves heat dissipation by 20–30% over SMD, reducing operating temperatures and preserving performance stability.

- Structural Integrity: Eliminating solder joints and wire bonds reduces failure points and enables finer pixel pitches (⩽0.9mm) for high-resolution applications.

Why COB enhances reliability for high-usage environments like control rooms and digital signage

The solid build of COB technology really shines in those always-on environments where downtime just won't cut it. We're talking control centers, TV production spaces, and those big digital displays in airports and malls. The way COB encapsulates everything cuts down on dead pixels by around 90% when compared to traditional SMD panels. Plus, it handles heat much better too, which means these displays last anywhere from 30% to maybe even 50% longer in warm conditions. And let's not forget about vibrations either. These screens can handle being near industrial equipment or placed in high traffic areas without breaking a sweat. All these features together mean fewer repairs needed over time and ultimately saves money across the board. Most installations run reliably for well over 60,000 hours before needing serious attention.

Flexible LED Display Cost Drivers: From Pixel Pitch to Installation Complexity

How size, curvature radius, and custom geometry affect LED display pricing

The price tag for flexible LED displays goes up quite a bit as things get physically complicated and geometrically intricate. When installations go past about 10 square meters, there's no getting around needing stronger structural support systems along with those precision modular connections between panels. That drives up both material costs and what engineers charge for their work. For curves tighter than 500mm radius, regular printed circuit boards just won't cut it anymore. Specialty flexible substrates become necessary instead, which typically adds anywhere from 30 to 50 percent extra onto the base materials alone. And then there are those really tricky shapes like free forms, concave surfaces, or multiple curved angles. These situations almost always call for specially made mounting brackets and professional installers who have proper certifications. Labor times shoot up by roughly 40 to 60 percent compared to straightforward flat surface installations.

Resolution, brightness (nits), IP rating, and color calibration as premium cost factors

Four technical specifications define premium pricing tiers:

- Pixel Pitch: Sub-P2.5 resolutions increase LED density exponentially—driving higher component and assembly costs.

- Brightness: Panels rated at 8,000+ nits require advanced thermal architecture and high-efficiency drivers.

- IP Rating: IP65/67 certification mandates specialized sealing materials, conformal coatings, and rigorous environmental testing.

-

Color Calibration: Factory-level uniformity (±0.003 dE) relies on calibrated optical instruments and extended test cycles.

Each tier upgrade typically incurs a 25–40% premium due to enhanced components, tighter quality control, and added validation steps.

COB vs SMD LED Displays: Total Cost of Ownership and Performance Trade-offs

Upfront investment comparison and long-term savings from reduced maintenance and higher yield

COB displays generally cost about 15 to 20 percent more upfront compared to similar SMD models because they require much more precise manufacturing steps like bonding components together, applying special resins, and careful curing processes. But when looking at places where screens run constantly, COB actually makes good financial sense over time. The sealed design means fewer dead pixels too - we're talking something like less than half a percent failures rate in most cases. That cuts down on repairs and keeps systems running smoothly without unexpected shutdowns. Studies from control room operators show around a 40% saving on overall costs after five years of continuous operation. Plus, better heat handling results in roughly 30% less electricity usage which not only saves money but also reduces the need for expensive air conditioning systems in server rooms and other high temperature environments.

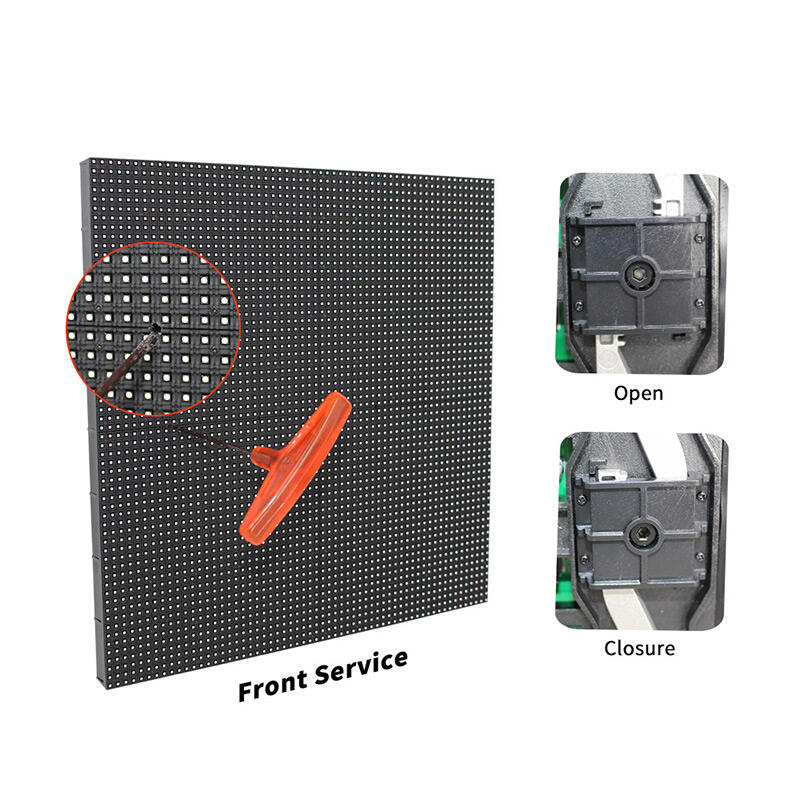

When SMD remains optimal: Budget constraints, fine-pitch availability, and serviceability needs

SMD still makes a lot of sense when money matters upfront, quick fixes in the field, or getting those really tiny pitches are what counts most. Take projects that have tight budgets below $50k or big screens over P1.5 pitch size. SMD tends to be much cheaper to get started with. The way it's built lets techs swap out single LEDs right at the site with regular soldering gear, so they don't have to replace whole modules or send stuff back to the factory like with COB technology. This flexibility really matters in event setups and temporary installations, because nobody wants to lose money waiting for repairs while shows run on schedule. Plus, right now SMD parts are just easier to find for those super small sub-P1.0 pitches needed in compact displays and dense installations. Many manufacturers simply can't keep up with demand for COB components at these sizes yet.

Real-World Applications of Flexible and COB LED Displays in Commercial Environments

Flexible LED displays are changing how businesses look and function thanks to their ability to bend and scale up or down as needed. Many stores now install these curved screens at their front entrances and inside as digital windows that catch shoppers attention and keep them lingering longer before making purchases. Museums and exhibition centers love them too because they can be moved around easily and rearranged for different displays without much hassle. When it comes to buildings themselves, architects are putting these displays on exterior walls and ceiling areas where lots of people pass by. The screens tile together seamlessly and work well from almost any angle, sometimes up to 160 degrees which means everyone gets a good view no matter where they stand. One fancy car dealership saw a huge jump in customer interaction when they wrapped their entire space with these flexible displays according to an industry report from last year.

COB displays are becoming the go to choice for places where reliability and picture quality just cant be compromised. Control rooms and TV studios depend on these displays because they have that sealed construction which keeps pixels working even after months of non stop use. In corporate boardrooms, businesses turn to COB technology when they need to show off those 4K presentations with HDR10+ content. The colors look spot on and there's no annoying glare messing up the view. For concerts and events, the massive 1 million to 1 contrast ratio makes all the difference in creating those stunning backdrops that really grab attention. Hospitals and banks appreciate another aspect too the screens dont flicker at all and meet strict lighting standards (under 19 UGR) so people can work for hours without their eyes getting tired. Hotel managers tell us these displays last around 30 percent longer than regular options, which means fewer replacements over time and significant savings in maintenance expenses.

FAQ

What are flexible LED displays made of?

Flexible LED displays are made using bendable polyimide films and micro-LED technology mounted on flexible PCB substrates.

How does COB technology differ from SMD?

COB technology mounts bare LED chips directly onto a PCB and encases them in protective resin, while SMD involves pre-packaging individual diodes. This makes COB more durable and better for thermal management.

What factors affect the cost of flexible LED displays?

The cost is affected by the size, curvature radius, custom geometry, resolution, brightness, IP rating, and color calibration of the display.

Why are COB displays preferred in high-usage environments?

COB displays are durable, have better heat management, and offer higher reliability with fewer dead pixels, making them suitable for control rooms and digital signage.