What Is an LED Display Panel? Definition and Core Functionality

LED display panels are basically flat screens made up of lots of tiny light emitting diodes arranged in grids to show images and videos by controlling how much light comes out. The magic happens through something called electroluminescence. When electricity flows through these special semiconductor materials inside each LED, they start glowing by producing tiny packets of light called photons. Because the LEDs themselves generate light rather than needing some kind of backlight behind them, these displays can get really bright while still saving power compared to other screen technologies. That's why we see them everywhere from digital billboards to smartphone screens nowadays.

Definition and Function of LED Display Panels

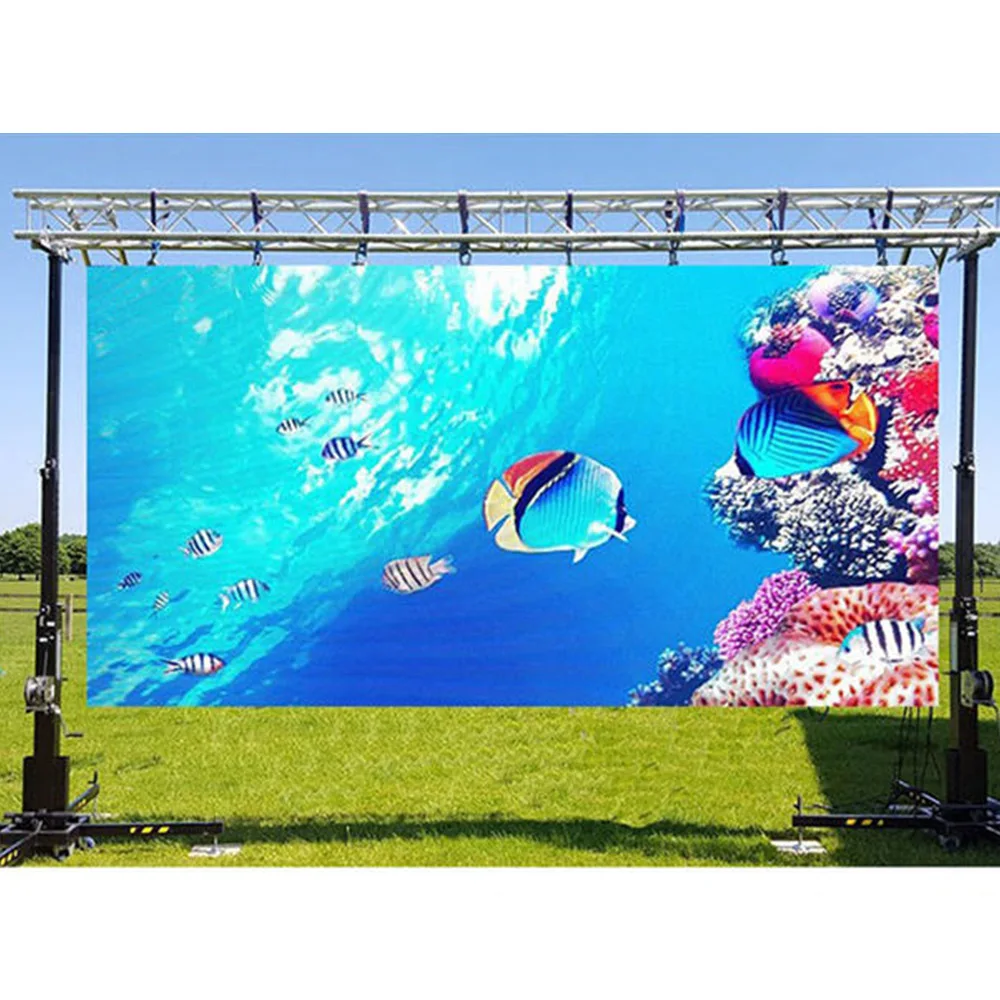

LED display panels serve as dynamic visual interfaces for digital signage, live events, and broadcast environments. Their primary function is to translate electrical signals into precise light patterns using millions of individually controllable red, green, and blue diodes, forming full-color imagery visible even in bright conditions.

Basic Structure of an LED Screen: From Diodes to Pixels

The hierarchical structure consists of three key layers:

- Diodes: Microscopic LEDs emitting red, green, or blue light

- Pixels: Clusters combining RGB diodes for color mixing

- Modules: Weather-resistant units containing 64–256 pixels, designed for seamless tiling

How Do LED Screens Work? A High-Level Overview

Video processors convert input signals into pixel-specific brightness and color data. Control systems distribute this information across all modules, updating individual diodes thousands of times per second to render fluid, flicker-free images without ghosting.

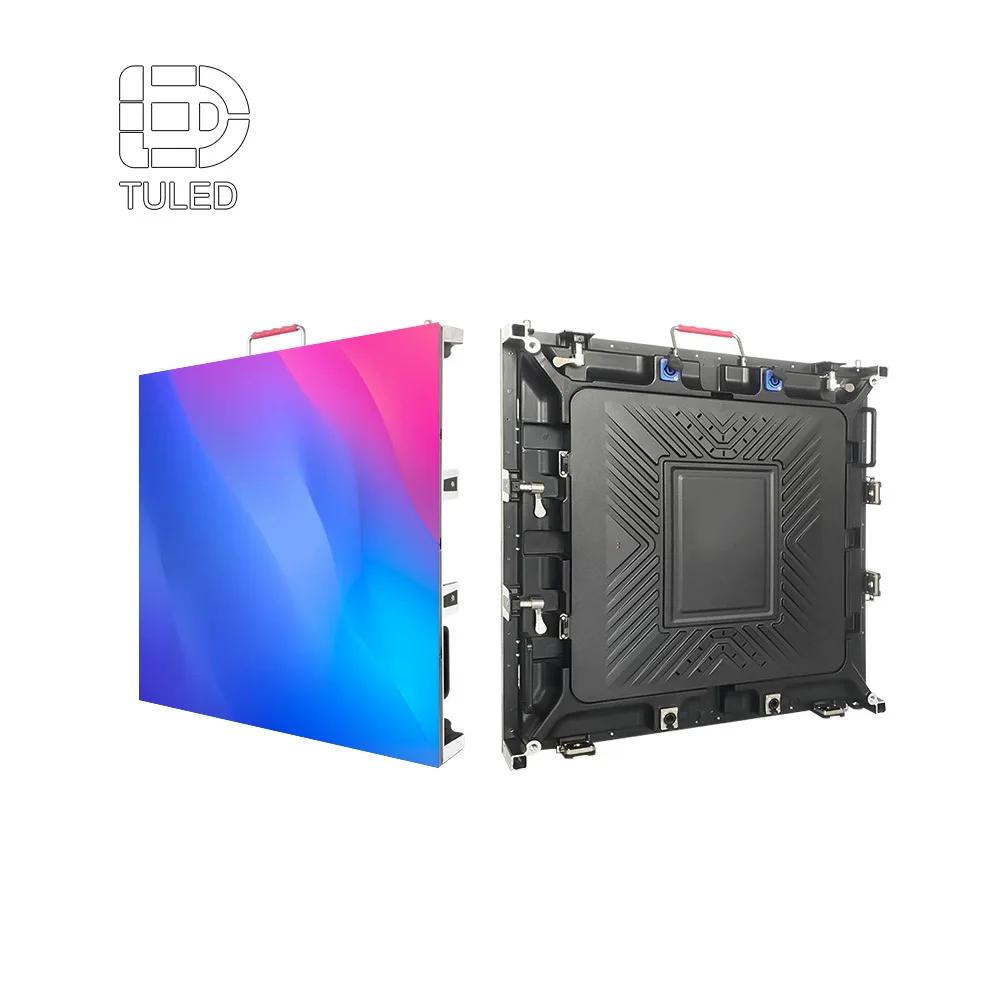

Key Components and Modular Design of LED Displays

Main Components of an LED Screen: Cabinet, Modules, Power Supplies, and Receiver Cards

Most modern LED displays rely on four main parts working together. First there's the cabinet itself, usually made from lightweight aluminum frames that keep everything aligned properly inside. These cabinets are pretty important because they need to withstand outdoor conditions while keeping all those delicate components secure. Inside these cabinets sit standard LED modules, generally around 320 by 160 millimeters in size. Each module contains hundreds of tiny RGB pixels along with driver chips and protective layers against environmental damage. Power distribution is handled through special supplies that provide steady 5 volts DC power. The system includes backup circuits so even if one part fails, the display stays operational about 99.9 percent of the time. Lastly, receiver cards function as central controllers, taking incoming video signals and converting them into specific instructions for individual pixels across the entire screen, often using fast Ethernet connections or fiber optic cables for maximum speed.

LED Modules and Pixel Pitch: Understanding Resolution Drivers

The term pixel pitch refers basically to how far apart the centers of neighboring pixels are from each other, which ultimately affects both image clarity and how close someone should stand to view a screen properly. Take a module with a 1.5 mm pitch for instance it manages to fit roughly 444 pixels into every square inch, making those big screens in shopping malls look incredibly sharp even at 8K resolution. What makes this possible? Advanced SMD packaging technology lets those tiny RGB diodes take up space as small as 0.4 mm squared. This advancement opens the door for super fine detail in displays with pitches as tight as 1 mm, something we see frequently in indoor environments like TV studios where broadcast quality matters most.

How LED Module Data Distribution Enables Synchronized Display

To maintain synchronization across vast arrays, FPGA-based controllers distribute compressed video signals via daisy-chained Cat6 cables, achieving <1 ms latency over 100-meter runs. Real-time error correction detects and bypasses faulty modules, while buffer systems prevent frame drops during signal interruptions, ensuring uninterrupted playback.

Step-by-Step: How an LED Display Panel Works from Signal to Light

From Signal Input to Light Emission: The Operational Workflow of LED Displays

When digital signals come from devices like media players or computers, they get into the display system where special hardware decodes them. What happens next is pretty interesting actually these signals match up with where everything is physically arranged on the screen, telling every single LED pixel exactly how bright it should be. Most displays work at around 60Hz, which means each tiny dot on the screen gets updated 60 times every second. This creates those smooth looking images we see without any annoying flickering, making it good enough for most everyday uses although gamers might want something faster for their needs.

Digital Signal Processing in LED Displays: Translating Images into Control Commands

The specialized chips inside these devices take all that raw image data and translate it into specific brightness and color commands for each LED. There's quite a bit going on here actually - things like matching pixels to the right spots on the screen grid, making sure resolutions line up properly, and adjusting grayscale so everything looks uniform across the display. Most newer setups work with 12 bits of color depth, which means they can create something like 68.7 billion different colors for each tiny light. This massive range allows for incredibly smooth color shifts and gradients that look almost exactly like real life photos when viewed up close.

Image Refreshing and Refresh Rate: Ensuring Smooth Visual Output

The refresh rate basically tells us how often a screen updates what we see on it. When looking at premium screens that hit 240Hz versus standard ones at 60Hz, there's a noticeable difference in clarity when watching something quick moving. Some tests show these faster panels cut down motion blur significantly, maybe around three quarters less than older tech. That's why gamers and sports fans tend to prefer them for their sharper visuals during action sequences. For setups with multiple panels working together, having synchronized timing controllers becomes really important. These components help keep everything aligned so frames don't get messed up or delayed when scenes change rapidly from one panel to another.

RGB Pixel Architecture and Full-Color Generation in LED Panels

The Role of RGB Clusters in LED Display Components and Pixel Structure

All LED displays work with RGB pixel structures basically. These displays have tiny groups of red, green and blue lights that make up each individual color point. Inside every pixel there are actually three smaller parts working together closely. They follow what's called the additive color method, so when different amounts of red, green and blue light mix together, they produce all sorts of colors we can see. When manufacturers go for smaller spaces between pixels, like around 1.5mm apart, they get way more pixels packed into each square meter over 44 thousand actually which means much sharper pictures especially when someone is looking at them from just a few feet away.

Color Formation Using RGB LEDs: Mixing Red, Green, and Blue Light

Colors appear when we tweak how bright each tiny red, green, and blue pixel gets inside those little clusters on screens. Take for instance what happens when someone cranks up both red at around 655 nanometers and green at approximately 520 nanometers together - boom, we see yellow! And if all three primary colors work equally hard, they mix into something resembling white light. There's this clever technique called pulse width modulation that gives manufacturers super fine grain control over brightness levels. Because of this technology, modern displays can trick our eyes into seeing roughly 16.7 million different shades even though there are only three basic colors involved. Our vision system works this way because humans naturally perceive color through three types of cone cells in the retina, which makes these combinations possible in the first place.

Achieving Millions of Colors Through Precise RGB Color Mixing

Today's display panels typically work with 8-bit up to 16-bit processing power, which gives them between 256 and around 65 thousand intensity levels for each color channel. The numbers get interesting when we look closer: an 8-bit setup can handle roughly 16.7 million different color mixes (that's 256 cubed). Move up to 10-bit technology and suddenly there are over a billion possible combinations available. Why does all this matter? Well, these finer gradations make a big difference when showing things like realistic skin tones or those smooth transitions in skies at sunset. The latest improvements in LED calibration tech have pushed color accuracy down to Delta E values below 2, something that satisfies even the strict requirements of broadcast quality standards in television production.

Control Systems and Signal Processing for Synchronized Visual Output

Synchronizing Thousands of Modules: The Role of Control Systems in Large LED Displays

Control systems at the center manage thousands upon thousands of modules down to individual pixels. These systems take the video signal coming in, break it down into specific instructions for displays, then send all that information out to the receiver cards inside every single module. The latest technology makes sure everything gets updated at the same time across the whole screen setup, so there are no annoying visual glitches or distortions when things happen fast on screen. Modern controllers can handle refresh rates as high as around 7,680 Hz now, which means they work great even during those super fast broadcasts where every millisecond counts.

Analog vs. Digital Control in Large-Scale LED Deployments: Performance and Reliability Considerations

Back in the day, most systems relied on analog control, but these days digital setups have taken over because they just work better. Take 4K signals for example. Digital tech can handle them in under 2 milliseconds, way quicker than the 15 to 20 milliseconds it takes for analog systems. This speed difference makes a big impact on reducing lag and making everything feel more responsive. Another plus is built-in error correction that fixes messed up data as it happens, while distributed processing lets resolutions scale all the way up to 16K without quality dropping off. Field tests show digital systems perform about 40% more reliably when humidity gets high, which matters a lot in certain industrial settings. We're also seeing some interesting hybrid solutions pop up lately, where companies use analog components for power delivery but switch to digital for actual signal processing. This mix seems to strike a good balance between getting things done efficiently and keeping operations stable.

FAQ

What are LED display panels used for?

LED display panels are used for digital signage, live events, and broadcast environments to create full-color imagery using controllable red, green, and blue diodes.

How do LED screens work?

LED screens work by converting input signals into specific brightness and color data, distributed by control systems to render images without flickering.

What is pixel pitch in LED displays?

Pixel pitch refers to the distance between the centers of neighboring pixels, affecting image clarity and ideal viewing distance.

How do RGB LEDs create colors?

Colors are created by adjusting the brightness of red, green, and blue pixels in the RGB clusters to form different color combinations.