Ինչպես աշխատում են LED ցուցիչները. Լույս արտանետող դիոդային տեխնոլոգիայի հիմքերը

Ինչ է LED ցուցիչը. LED տեխնոլոգիայի հիմնարար սկզբունքներ

LED ցուցիչը, որն ընդհանրապես կրճատվում է՝ որպես լույս արտանետող դիոդ, աշխատում է որպես թվային էկրան, որտեղ փոքր կիսահաղորդչային դիոդներ ստեղծում են տեսանելի պատկերներ: Այն, ինչ տարբերում է այն LCD էկրաններից, այն է, որ նրանց համար չի պահանջվում ետևի լուսավորության համակարգեր: Փոխարենը, յուրաքանչյուր LED-ն սեփական լույսն է արտադրում հոսանքի միացման դեպքում: Սա նշանակում է ավելի պայծառ պատկեր՝ շատ պայծառ ներքին տարածքների համար, երբեմն հասնելով մոտ 2500 նիտ այդ մեծ արտաքին էկրանների վրա: Իրական կառուցվածքը ներառում է գալիումի նիտրիդի (GaN) նման հատուկ նյութերի շերտեր, որոնք օգնում են կառավարել լույսի արտանետումը ատոմային մակարդակում: Որպես արդյունք՝ այս ցուցիչները կինելու են ավելի քիչ էներգիա, քան հին ձևի կալորիային լամպերը, հավանաբար էներգիայի ծախսերը 95 տոկոսով փոքրացնելով՝ ըստ տարբեր ուսումնասիրությունների:

LED ցուցիչների հիմնական աշխատանքը և լույսի արտադրումը

LED-ները լույս են արտադրում էլեկտրալուսարձակմամբ , որտեղ էլեկտրոնները անցնում են կիսահաղորդչի p-n անցումը: Երբ լարում է կիրառվում.

- N-տիպի շերտի էլեկտրոնները միաձուլվում են p-տիպի շերտի անցքերի հետ

- Էներգիան արձակվում է որպես ֆոտոններ՝ 450նմ (կապույտ) և 630նմ (կարմիր) երկարության ալիքների միջակայքում

- Ֆոսֆորային ծածկույթները կապույտ LED-ները փոխարկում են սպիտակ լույսի, երբ այն անհրաժեշտ է

Այս ուղղակի փոխակերպումը վերացնում է ֆիլտրների կամ արտաքին լուսավորության կարիքը՝ ապահովելով արագ 0.01մվ-ի պատասխանման ժամանակ, ինչը հիանալի է անընդհատ տեսանյութերի վերարտադրման համար:

Կիսահաղորդիչների դերը լույսի արդյունավետ արտադրման մեջ

Գագաթավոր կիսահաղորդչային համաձուլվածքները ուղղակիորեն ազդում են կատարման վրա.

| Նյութի հատկությունը | Ազդեցությունը էկրանի վրա | Տարածված միացություններ |

|---|---|---|

| Գոտու էներգիա | Լուսավոր գույն | GaN (Կապույտ/Սպիտակ) |

| Ic հետագծություն | Լուսային կայունություն | AlGaInP (Կարմիր/Նարնջագույն) |

| Էլեկտրոնային շարժունակություն | Էներգետիկ արդյունավետություն | InGaN (Կանաչ) |

Արտադրողները այս նյութերը օպտիմալացնում են՝ հասնելով 100,000 ժամ աշխատանքի ընդհանուր ժամանակի, միաժամանակ աջակցելով 16,7 միլիոն գույների: LED էկրանները, չունենալով շարժվող մասեր, հուսալիորեն են աշխատում ծայրահեղ ջերմաստիճանների դեպքում (-40°C-ից մինչև 70°C):

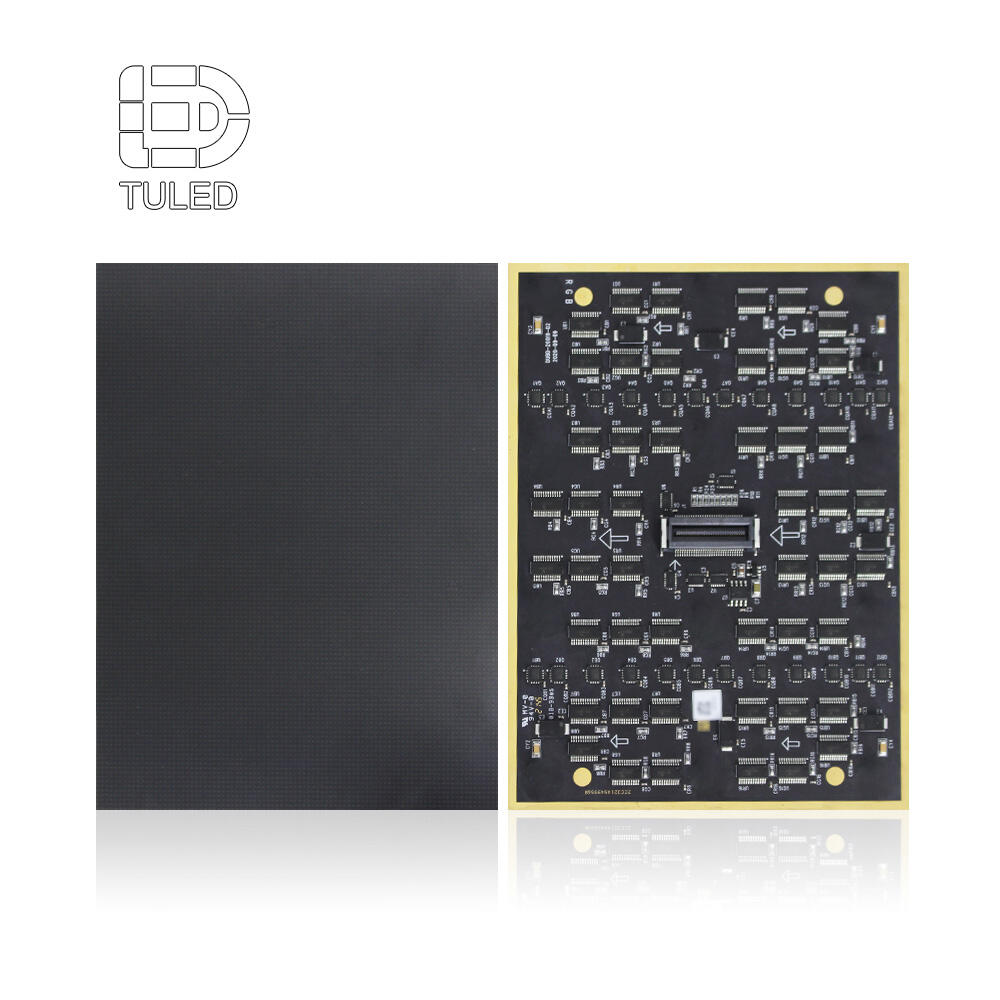

Հիմնական բաղադրիչներ՝ վահանակներ, կառավարման սալիկներ և պիքսելային մատրիցներ

Այսօրվա LED էկրանները հիմնված են երեք հիմնական մասերի համատեղ աշխատանքի վրա՝ վահանակների կառավարման սխեմաներ, կառավարման տախտակներ և փոքրիկ պիքսելների դասավորություններ, որոնք տեսնում ենք էկրանին: Վահանակների կառավարման սխեմաները վերահսկում են, թե որքան էլեկտրականություն է ստանում յուրաքանչյուր փոքրիկ LED-ը, որպեսզի ամեն ինչ միևնույն մակարդակով լուսարձակի, նույնիսկ երբ դրանք միլիոնավորն են և խիտ տեղավորված: Կառավարման տախտակները մշակում են HDMI կաբելներից կամ ցանցային միացումներից ստացված տվյալները՝ ապահովելով, որ էկրանին ցուցադրվողը գրեթե ակնթարթորեն տեղի ունենա: Ինչ վերաբերում է ինքն պիքսելներին, դրանք կազմված են կարմիր, կանաչ և կապույտ լույսերի խմբերից, որոնք իրար մոտ են դասավորված՝ ներքին տարածքներում հեռավորությունը կարող է կազմել մոտ 1,5 մմ, իսկ արտաքին ցուցադրումների դեպքում ավելի մեծ հեռավորություն է անհրաժեշտ՝ երբեմն հասնելով 10 մմ-ի՝ հեռվան լավ տեսանելիություն ապահովելու համար: Այս բոլոր մասերի համատեղված աշխատանքը նշանակում է, որ այս ժամանակակից ցուցադրումները կարող են շատ երկար ժամանակ անցկացնել փոխարինում չպահանջելով, թեև ոչ ոք իրականում չի հաշվում այդ հարյուր հազարից ավել ժամերը, trừ եթե աշխատում է սպասարկման մասնաճյուղում:

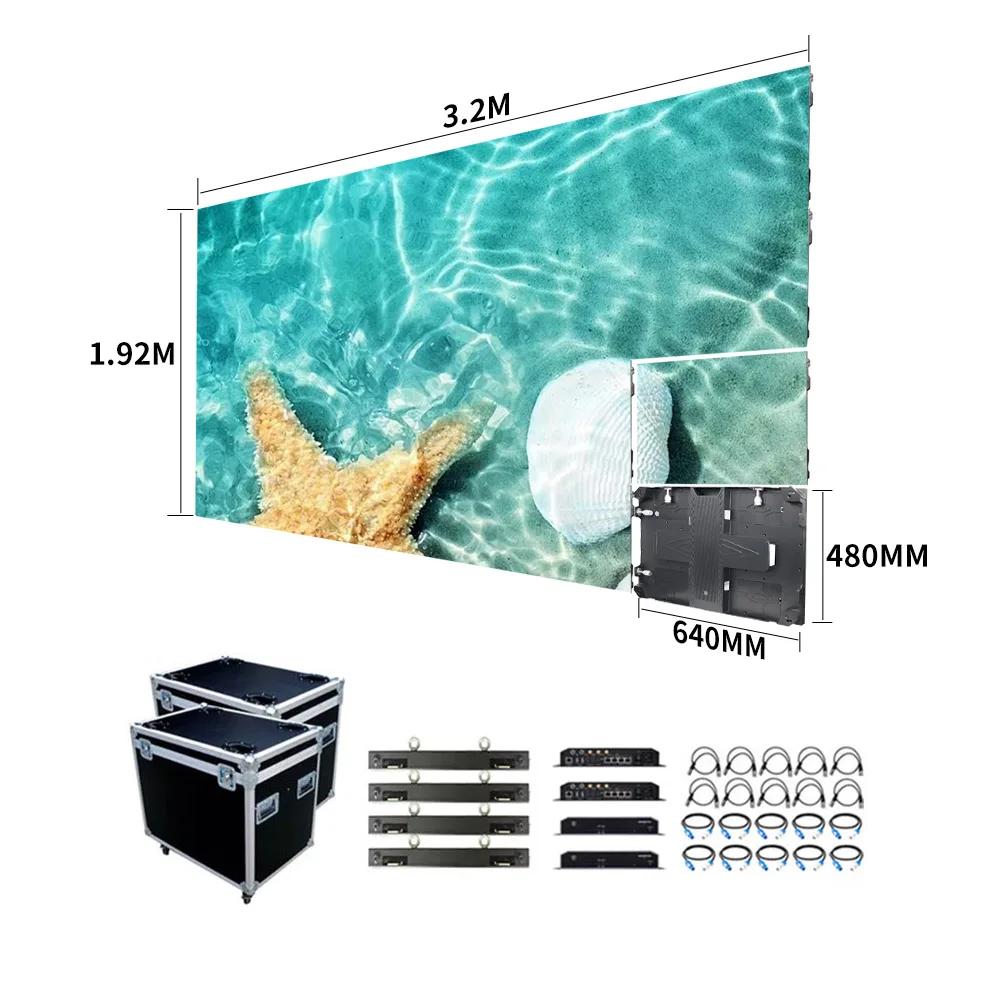

Պիքսելների հեռավորություն, լուծաչափություն և մոդուլի կոնստրուկցիա

Երբ խոսքը լեդերի միջև հեռավորության մասին է, այսպես կոչված պիքսելային քայլի մասին, դա իրականում ազդում է նկարի պարզության վրա և այն հեռավորության վրա, որից մարդիկ պետք է հեռացնեն, որպեսզի այն ճիշտ տեսնեն: Վերցրեք, օրինակ, 1,5 մմ քայլը, որը մոտ 3 մետր հեռավորությունից տալիս է մոտ 16K լուծաչափ: Դա հիանալի աշխատում է խանութներում մեծ թվային ցուցադրումների համար: Մյուս կողմից՝ հսկայական ստադիոնների էկրանները սովորաբար օգտագործում են մոտ 10 մմ քայլ, քանի որ մարդիկ դրանք դիտում են շատ ավելի հեռուից, սովորաբար մոտ 30 մետր հեռավորության վրա: Ամենատարածված ստանդարտ լեդ վահանակները սովորաբար 320 x 160 միլիմետր չափսեր ունեն և պարունակում են 256-ից մինչև հազարից ավելի առանձին պիքսելներ, որոնք պաշտպանված են ամուր ալյումինե շրջանակներում՝ ստեղծված երկարակեցության համար: Արտաքին տեղադրումների համար, որտեղ անձրևը և փոշին մտահոգություն են առաջացնում, արտադրողները մոդուլներ են ստեղծում IP65 վարկանիշով, որպեսզի դրանք կարողանան դիմանալ ցանկացած եղանակի: Ներքին տարբերակները ավելի շատ կենտրոնանում են նրանց բարակ և նուրբ լինելու վրա, երբեմն նույնիսկ 2,9 մմ հասնելով հաստությամբ՝ այն ավելի խիտ տարածություններում տեղավորելու համար՝ առանց ծավալուն տեսք ունենալու:

Ինչպես կառուցվածքային նախագծումը ազդում է կատարողականի և մասշտաբավորման վրա

Համակարգը մասշտաբավորվում է այն փոխկապակցված կադրերի շնորհիվ, որոնք կարող են ապահովել մեկ վահանակից մինչև 500-ից ավելի վահանակներ։ Արտաքին տեղադրման դեպքում այս կառույցները հիմնված են ամուր պողպատե կադրերի վրա՝ հագեցած ակտիվ սառեցման համակարգերով։ Ներքին ջերմաստիճանը պահպանվում է մոտ 25 աստիճան Ցելսիուս՝ ±5 աստիճանով, իսկ էկրանները արտադրում են շատ պայծառ պատկեր՝ 2500-ից մինչև 5000 նիտ լուսարձակմամբ, որն ապահովում է տեսանելիություն նույնիսկ ուժեղ արևի պայմաններում։ Ներքին կիրառման դեպքում արտադրողները նախընտրում են թեթև ալյումինե մատերիալներ՝ պասիվ սառեցման լուծումներով, իսկ պայծառությունը իջնում է 800-ից մինչև 1500 նիտ՝ քանի որ շրջապատող լույսի մակարդակը ավելի ցածր է։ Այս համակարգերի հատկանիշն այն է, որ դրանք շատ ճշգրիտ են միմյանց հետ կապվում։ Թույլատրելի շեղումները 0,1 մմ-ից ցածր են, որի շնորհիվ ոչ ոք տեսնում է միջակայքեր, ինչը թույլ է տալիս ստանալ գեղեցիկ կորացված դիզայն՝ ծռման անկյուններով 15 աստիճանից մինչև 90 աստիճան։ Եվ իրենց ամուր կառուցվածքի շնորհիվ այս համակարգերը հուսալի են աշխատում՝ անկախ նրանից, որ ջերմաստիճանը իջնի -30 աստիճան Ցելսիուսի կամ բարձրանա 60 աստիճան Ցելսիուսի:

ԱԼԵԿՏՐՈԼՈՒՍԱԴԻՈԴԱՅԻՆ ԷԿՐԱՆՆԵՐԻ ՏԵՍԱԿՆԵՐԸ՝ OLED, MicroLED ԵՎ ՈՒՂՂԱԿԻ ԴԻՏՄԱՆ LED-ՆԵՐԻ ՀԱՄԵՄԱՏՈՒԹՅՈՒՆ

ԳԼԽԱՎՈՐ ՏԵՍԱԿՆԵՐԸ՝ OLED, LED-ով ետևից լուսավորվող LCD ԵՎ ՈՒՂՂԱԿԻ ԴԻՏՄԱՆ LED

Էկրանների շուկան հիմնականում բաժանվում է երեք հիմնական տեսակների: Դիտման անմիջական ԼԱՍ (LED) տեխնոլոգիան աշխատում է՝ օգտագործելով փոքրիկ լուսարձակ դիոդներ, որոնք դասավորված են պիքսելների ցանցերում, ինչը դրանք դարձնում է իդեալական խոշոր էկրանների համար, ինչպես օրինակ՝ սպորտային մարզադաշտերում տեղադրված հսկայական էկրանները: Հաջորդը OLED-ն է՝ օրգանական լույս արտանետող դիոդ, որտեղ յուրաքանչյուր պիքսելը իր սեփական լույսն է արտադրում օրգանական նյութերի միջոցով: Սա ՕԼԱՍ-ներին տալիս է այն հիանալի հակադրության ցուցանիշը, որը մարդիկ այնքան են սիրում բարձր դասի հեռուստացույցներում և թանկարժեք հեռախոսներում: Շատերը սխալմամբ կարծում են, որ LED ետնալուսավորվող LCD էկրանները ԼԱՍ էկրաններ են, սակայն իրականում դրանք պարզապես LED-ներն են օգտագործում հետնալուսավորման համար հեղուկ բյուրեղային վահանակների համար՝ առանց իրականացնելու յուրաքանչյուր պիքսելի առանձին լուսավորում: 2025 թվականի շուկայի զեկույցները ցույց են տալիս, որ OLED-ն զբաղեցնում է վերին մակարդակի շուկայի մոտ 62 տոկոսը, մինչդեռ դիտման անմիջական ԼԱՍ-ը շարունակում է գերիշխել առևտրային համակարգերի մեծ մասում՝ անկախ նորագույն տեխնոլոգիաների շուրջ տարածված քննարկումներից:

ՄիկրոLED և սովորական LED՝ արդյունավետության և տեխնոլոգիական տարբերություններ

ՄիկրոLED տեխնոլոգիան վերցնում է սովորական LED-ները և բարձրացնում մեկ այլ մակարդակի՝ ներառելով 100 միկրոմետրից փոքր չափերով մանր դիոդներ: Սա հնարավորություն է տալիս շատ ավելի խիտ պիքսելային դասավորությունների և ընդհանուր առմամբ ավելի բարձր արդյունավետության, քան նախկինում տեսել ենք: Սովորական LED-ների նման տպագրված շղթայի վրա տեղադրված լինելու փոխարեն՝ MicroLED չիփերը անմիջապես տեղադրվում են տարբեր տեսակի մակերեսների վրա: Ի՞նչ արդյունք է ստացվում. դիսփլեյներ, որոնք կարող են հասնել 4000 նիտ լուսային ինտենսիվության՝ համաձայն 2025 թվականի Display Standards Consortium-ի տվյալների, և նաև առաջարկում են գունային ծավալի մոտ 99,3% ճշգրտություն: Սակայն այստեղ կա մեկ խնդիր: Այս առաջադեմ դիսփլեյների արտադրությունը մնում է բարդ և թանկարժեք գործընթաց: Արտադրման ծախսերը մոտ 8-ից 12 անգամ ավելի են լինում, քան OLED սալիկների արտադրության ծախսերը: Այս գնային տարբերության պատճառով մեծամասնությունը MicroLED տեխնոլոգիան տեսնում է միայն բարձր կարգի կիրառություններում, ինչպես օրինակ՝ հարուստ հյուրանոցներում տեղադրված վիդեո պատերը կամ հատուկ նշանակության տեղադրումները, որտեղ բյուջեն հատուկ կարևոր չէ:

Ներքին և արտաքին LED դիսփլեի կառուցվածքները և մաշվածության նկատմամբ դիմացկունության պահանջները

Նախագծերը զգալիորեն տարբերվում են՝ կախված շրջակա միջավայրից.

- Ներքին էկրաններ կենտրոնանում են պիքսելների խտության (1,2–2,5 մմ քայլ) և գույների ճշգրտության վրա՝ աշխատելով 800–1500 նիտ լուսային ինտենսիվության դեպքում՝ փայլի նվազեցման նպատակով

- Արտաքին դիսփլեներ պահանջում են IP65+ կամ ավելի բարձր աստիճանի անձրևակային պաշտպանություն, բարձր լուսային ինտենսիվություն (5000–10000 նիտ)՝ արևի լույսին դիմադրելու համար, ինչպես նաև հզորության պահերազրյալ համակարգեր

2025 թվականի մաշվածության ուսումնասիրությունը ցույց տվեց, որ արտաքին միավորները 50,000 ժամ անընդհատ աշխատանքից հետո պահպանում են լուսային ինտենսիվության 92%-ը՝ ներքին անալոգներից 40%-ով ավելի երկար ընթացքով՝ նույն շահագործման պայմաններում

Բացատրելով շփոթմունքը. Արդյո՞ք բոլոր «LED դիսփլեները» իրոք LED-հիմնված են

Մարքեթինգային աշխարհը հակված է իրական LED տեխնոլոգիան շփոթել այն LED-ետևի լուսավորվող LCD էկրանների հետ, որոնք մենք ամենուր ենք տեսնում: Երբ մարդիկ խոսում են LED ցուցիչների մասին, իրականում նրանք նկատի ունեն ուղղակի տեսանելի LED վահանակներ, OLED-ներ և MicroLED համակարգեր, որտեղ յուրաքանչյուր փոքրիկ պիքսելը իր սեփական լույսի աղբյուրն է արտադրում: Այսօր խանութների թաղանթներին առկա այսպես կոչված «LED» ապրանքների մեծամասնությունը իրականում LED-ետևի լուսավորվող LCD-ներ են, որոնք կազմում են մոտ 78% սպառողների կողմից գնված ապրանքներից: Սակայն այս ցուցիչները չեն կարող համապատասխանել իրական LED-ների աշխատանքային ցուցանիշներին: Վերցրեք, օրինակ, հակադրության հարաբերակցությունը՝ մինչդեռ OLED-ները հասնում են անվերջ 1-ի, ստանդարտ LED-ետևի լուսավորվող մոդելները հասնում են միայն 1200:1: Նաև տուժում է դիտման անկյունը՝ իջնելով 178 աստիճանից մինչև ընդամենը 160 աստիճան: Եվ եկեք մի մոռանանք այն մասին, թե որքան են այս սարքերը տևում: Իրական LED ցուցիչները, ընդհանուր առմամբ, երեք անգամ ավելի երկար են տևում, քան նրանց ետևի լուսավորվող համակարգերը, ինչը բացատրում է նաև ինչու են դրանք այդքան շատ տարբերվում գնով:

LED Էկրաններում Պատկերի Որակի Գործոնները՝ Գույն, Լուսավորություն և Տեսանելիություն

Գույների Ստեղծումը՝ Օգտագործելով RGB Պիքսելներ և Լրացուցիչ Գունային Խառնուրդ

LED էկրանները կարմիր, կանաչ և կապույտ (RGB) ենթապիքսելների միջոցով ստեղծում են կենդանի պատկեր: Ինտենսիվության մակարդակները փոխելով՝ նրանք ավելի քան 16,7 միլիոն գույն են ստեղծում լրացուցիչ խառնման միջոցով: Այն էկրանները, որոնք համապատասխանում են DCI-P3 գունային տիրույթի 95%-ին, 23%-ով ավելի ճշգրիտ վերարտադրում են գույները, քան ստանդարտ RGB կառույցները (DisplayMate 2023), ինչը դրանք անհրաժեշտ դարձնում է կինոյի և բժշկական վիզուալացման համար:

Լուսավորություն, Կոնտրաստի Հարաբերակցություններ և Գունային Ճշգրտության Չափորոշիչներ

Լուսավորության պահանջները տարբերվում են կախված տեղադրման վայրից. արտաքին էկրաններին անհրաժեշտ է 4500+ նիտ լուսավորություն օրվա լույսի տակ տեսանելիության համար, իսկ ներքին մոդելների համար օպտիմալ է 600–800 նիտը՝ աչքի կենտրոնացման կանխարգելման համար: 5000:1-ից բարձր կոնտրաստի հարաբերակցությունը պահպանում է խորությունը մուգ տեսարաններում՝ կարևոր սիմուլյացիայի և կառավարման սենյակների համար: Ուսումնասիրությունները ցույց են տվել, որ բարձր կոնտրաստով էկրանները կրթական միջավայրում բովանդակության պահպանումը բարելավում են 18%-ով:

| Факտոր | Ներքին Պահանջներ | Արտաքին Պահանջներ |

|---|---|---|

| Օպտիմալ Լուսավորություն | 600-800 նիտ | 4500-7000 նիտ |

| Նվազագույն հակադրության հարաբերակցություն | 3000:1 | 5000:1 |

| Շրջակա միջավայրի վրա կենտրոնացում | Գույնի կայունություն թույլ լուսավորության պայմաններում | Բարձր փայլի նվազեցում և ջերմային կայունություն |

Դիտման անկյուններ և շրջակա միջավայրի տեսանելիություն (արև, թույլ լույս)

Լավագույն LED կառուցվածքները պահպանում են գույների և պայծառության լավ տեսքը գրեթե ամբողջ 160 աստիճանանոց անկյունում, ինչը դրանք շատ օգտակար է դարձնում այն տեղերում, որտեղ մարդիկ շատ են շարժվում, օրինակ՝ օդանավակայաններում: Արտաքին տեղադրումների համար արտադրողները սկսել են օգտագործել հատուկ անդրադարձնող ծածկույթներ՝ հարմարեցնելով գունային ջերմաստիճանը մոտ 5500K, որպեսզի արևի լույսը չխանգարի էկրանի աշխատանքին: Ներքին վահանակները ավելի տարբեր են աշխատում. դրանք սովորաբար հիմնված են ցրված օպտիկական կառուցվածքների վրա, որոնք լույսը ավելի հավասարաչափ են տարածում ամբողջ տարածքով: Վերաբերյալ խոնավության դիմադրությանը՝ IP65 կնքված էկրանները ժամանակի ընթացքում կորցնում են պայծառության 5 տոկոսից պակասը՝ համեմատած սովորական մոդելների հետ: Որոշ լաբորատոր փորձարկումներ ցույց են տալիս, որ այս caրձադաս տարբերակները կեղծված միջավայրում ծայրահեղ եղանակային պայմանների նկատմամբ արձագանքում են մոտավորապես երեք անգամ ավելի լավ, քան ստանդարտ սարքավորումները:

LED էկրանների կիրառություններն ու առավելությունները ժամանակակից արդյունաբերության մեջ

Թվային ցուցադրում և LED տեսապատեր առևտրի, կորպորատիվ և զվարճանքի ոլորտներում

LED էկրանները բարձրացնում են ներգրավվածությունը՝ շնորհիվ դինամիկ թվային ցուցադրման: Առևտրում 83%-ը գնորդներից ավելի երկար ժամանակ են անցկացնում տեսապատերի մոտ (2024 թ. LED էկրանների շուկայի զեկույց): Կորպորացիաները օգտագործում են կորացված LED պատեր ամբողջական տվյալների ներկայացման համար, իսկ զվարճանքի վայրերը ստեղծում են հսկայական մոդուլային էկրաններ՝ կենդանի իրադարձությունների համար:

| Դիմում | Հիմնական օգուտ |

|---|---|

| Մանրածախ խանութների ցուցափեղկեր | ոտքի վրա եղած հոսքի 42%-ով բարձր պահպանում |

| Կոնցերտային սցենա | 20 հազարից ավելի հանդիսատեսի համար 360° տեսանելիություն |

| Խորհրդարանների տեղադրումներ | Իրական ժամանակում տվյալների տեսողական ներկայացման հնարավորություններ |

LED էկրաններ տրանսպորտի հանգույցներում, առողջապահության և հանրային տարածքներում

Օդանավակայաններն ու հիվանդանոցները կախված են եղանակին դիմադրող LED համակարգերից՝ իրական ժամանակում թարմացումներ ստանալու համար, որը 31%-ով կրճատում է ուղևորների հարցումները: Բժշկական հաստատությունները վիրահատարաններում օգտագործում են հակամիկրոբայական ծածկոցով LED սալիկներ՝ միավորելով վարակի վերահսկումը 99,8% գունային ճշգրտության հետ՝ ախտորոշման ճշգրտության համար:

LED տեխնոլոգիայի էներգաարդյունավետությունը, ծառայողական վայրը և շահագործման առավելությունները

Ժամանակակից LED էկրանները 60% պակաս էներգիա են օգտագործում, քան սովորական LCD-ները, և տևում են 100,000 ժամից ավելի՝ համարժեք լինելով անընդհատ աշխատանքի 11 տարվա (2023 թ. առևտրային AV չափորոշիչներ)։ Այս տևողականությունը հանգեցնում է 74% ցածր սպասարկման ծախսերի՝ համեմատած նեոնային ցուցանակների հետ, ինչը LED-ները դարձնում է արդյունավետ լուծում արդյունաբերության տարբեր ոլորտներում:

Հաճախ տրամադրվող հարցեր

Ինչն է տարբերում LED էկրանը LCD-ից:

LED էկրանները լույս ստեղծելու համար օգտագործում են առանձին LED-ներ, առաջարկելով ավելի պայծառ պատկերներ՝ առանց հետնալուսավորման անհրաժեշտության, ի տարբերություն LCD-ների, որոնք հիմնված են հետնալուսավորվող հեղուկ բյուրեղային սարքերի վրա:

Ի՞նչ է պիքսելի քայլը և ինչու է կարևոր

Պիքսելների միջև հեռավորությունը վերաբերում է LED-ների միջև հեռավորությանը էկրանում, որը ազդում է պատկերի պարզության և օպտիմալ դիտման հեռավորության վրա:

Ինչպե՞ս են MicroLED-ները տարբերվում սովորական LED-ներից:

MicroLED-ները փոքր են սովորական LED-ներից, թույլ տալով ավելի խիտ պիքսելային դասավորություն և բարելավված արդյունավետություն, սակայն ավելի թանկ են արտադրման համար:

Արդյո՞ք բոլոր LED էկրանները իրոք LED-հիմնված են:

Ոչ, շատ այնպիսի էկրաններ, որոնք կոչվում են LED էկրաններ, հատկապես LED-հետնալուսավորվող LCD-ները, իրականում իսկական LED էկրաններ չեն, որտեղ յուրաքանչյուր պիքսել ստեղծում է իր սեփական լույսը: