ՍԻԴ դիսփլեյների աշխատանքի հիմնարար սկզբունքը

ՍԻԴ դիսփլեյներում լույսի արձակման հիմնարար սկզբունքը

LED էկրանները աշխատում են էլեկտրոլյումինեսցենցիա անվան երևույթի շնորհիվ: Ըստ էության, սա նշանակում է, որ երբ էլեկտրական հոսանք է անցնում դիսփլեյի ներսում գտնվող հատուկ կիսահաղորդչային նյութերով, դրանք ինքնուրույն լույս են արտադրում: LCD էկրաններից հիմնական տարբերությունն այն է, որ LCD-ներին անհրաժեշտ է առանձին ետևի լուսավորության աղբյուր, իսկ այս ցուցիչների յուրաքանչյուր LED-ն ստեղծում է իր սեփական լույսը: Այդ իսկ պատճառով որոշ բարձր կարգի մոդելներ կարող են հասնել մոտ 10,000 նիտ լուսային ինտենսիվության, ինչը դարձնում է դրանք արևի ուղիղ շողերի տակ էլ արտակարգապես տեսանելի՝ համաձայն անցյալ տարվա DisplayMate հետազոտության: Այս ինքնալուսավորման մոտեցման մեկ այլ առավելություն էլ այն է: Փորձարկումները ցույց են տվել, որ LED ցուցիչները սովորաբար 40 տոկոսով պակաս էներգիա են օգտագործում սովորական LCD տեխնոլոգիայի համեմատ: Բացի այդ, նրանք ավելի լավ են մշակում գույները՝ գրեթե ամբողջությամբ ընդգրկելով DCI-P3 գունային տիրույթը, ինչը տարբեր սարքերում և պայմաններում պատկերները ավելի կենդանի և իրականին նման դարձնում:

Ինչպես են պիքսելներն ու ենթապիքսելները ստեղծում տեսանելի պատկերներ

Ժամանակակից LED էկրանները ստեղծում են պատկերներ՝ օգտագործելով RGB (կարմիր, կանաչ, կապույտ) ենթապիքսելների փոքրիկ խմբեր, որոնք կազմում են յուրաքանչյուր տեսանելի պիքսել: Երբ արտադրողները կարգավորում են յուրաքանչյուր ենթապիքսելի լուսայնությունը անհատապես՝ օգտագործելով ինչ-որ բան, ինչը կոչվում է իմպուլսային լայնության մոդուլացիա, նրանք կարողանում են ստանալ շուրջ 16,7 միլիոն տարբեր գույն էկրանի վրա: Իսկ իսկական վերաղի դիսփլեները գնում են ավելի հեռու՝ օգտագործելով micro LED տեխնոլոգիան, որտեղ պիքսելների միջև հեռավորությունը իջնում է 1 մմ-ից ցած: Այս առաջադեմ վահանակները ապահովում են 4K լուծաչափ, սակայն տարածքի մեկ միավորում պարունակում են գրեթե երեք անգամ ավելի շատ պիքսելներ, քան սովորական OLED էկրանները՝ ըստ 2023 թվականին SID կոնֆերանսում ներկայացված տվյալների:

Կիսահաղորդիչ նյութերի դերը LED դիսփլեների գործառույթներում

Գալիումի նիտրիդը (GaN) և ինդիում-գալիումի նիտրիդը (InGaN) հիմնական կիսահաղորդիչ միացություններն են, որոնք օգտագործվում են LED-ների ստեղծման համար: Այս նյութերը թույլ են տալիս.

- Երկայնության ճշգրիտություն : ±2նմ թույլատվություն՝ հաստատուն գունային ելքի համար

- Ջերմային կայունություն : Հուսալի աշխատանք մինչև 125°C

- Երկարակեցություն : Կրճատված էլեկտրոնների արտահոսքի պատճառով շահագործման ընդհանուր ժամանակը կարող է հասնել 100,000 ժամի (Compound Semiconductor Week 2024)

Նրանց քվանտային հարթակները անմիջապես էլեկտրական էներգիան փոխարկում են լույսի՝ ի հայտնի 85 %-ով ավելի բարձր լուսային արդյունավետություն ցուցաբերելով, քան ֆոսֆորի հիմքի վրա հիմնված լուծումները:

LED դիսպլեյի տեխնոլոգիայի համեմատությունը LCD-ի և OLED-ի հետ

| Հատկություն | LED էկրան | Kristalական 示 | OLED |

|---|---|---|---|

| Հակադրության հարաբերակցություն | 1,000,000:1 | 1,500:1 | 1,000,000:1 |

| Առավելագույն պայծառություն | 10,000 նիտ | 1,000 նիտ | 800 նիտ |

| Պատրաստման ժամանակ | 0.01մվ | 4մվ | 0.1մվ |

| 📐Служебный срок | 100 հազար ժամ | 60 հազար ժամ | 30 հազար ժամ |

Տվյալների աղբյուր՝ Display Technology Benchmark 2023

LED տեխնոլոգիան գերազանցում է LCD-ներին լուսարձակման, հակադրության և էներգաօգտագործման արդյունավետությամբ, միաժամանակ խուսափելով OLED-ներին բնորոշ այրման խնդրից: Դրա մոդուլային կառուցվածքը թույլ է տալիս հարթ մասշտաբավորում՝ կրող սարքերից սկսած մինչև ստադիոնային չափերով տեսապատեր, որտեղ լատենտությունը պահպանվում է 2 միլիվայրկյանի սահմաններում (SMPTE 2024 հեռուստարդյունաբերության ստանդարտներ):

LED ցուցիչների համակարգերում օգտագործվող հիմնական նյութեր և բաղադրիչներ

Հիմնական կիսահաղորդչային նյութեր՝ Գալիումի նիտրիդ և Ինդիում-Գալիումի նիտրիդ

Գալիումի նիտրիդը, կամ կրճատ՝ GaN-ը, հիմնականում այն է, ինչը կապույտ LED-ների ստեղծումն է հնարավոր դարձնում: Երբ այն խառնվում է ինդիումի հետ՝ ստեղծելով InGaN համաձուլվածքներ, արտադրողները կարող են կարգավորել տարբեր ալիքային երկարություններով ճառագայթվող լույսի քանակը, ինչը նշանակում է, որ ստանում ենք նաև գեղեցիկ կանաչ և կապտականաչ գույներ: Այս կիսահաղորդչային նյութերի իրական հիասքանչ հատկությունն այն է, որ նրանք կարող են էլեկտրական հոսանքը անմիջապես փոխարկել լուսային մասնիկների այդ փոքրիկ քվանտային հորերում: Վերաբերյալ արդյունաբերության վերջերս հրապարակված տվյալների, GaN-ի վրա հիմնված LED-ները ներկայումս ցուցադրում են 1 քառ. սմ-ին 100-ից պակաս դեֆեկտներ: Այս ցածր դեֆեկտների քանակն էլ բացատրում է, թե ինչու են մեծ չափերի LED էկրանների գույները այնքան համազանգված ամբողջ մակերևույթի վրա:

Տպագրված հաղորդակիցներ և ջերմային կառավարում LED էկրանների դիզայնում

Բազմաշերտ մուտքագրված սխեմաները, որոնք օգտագործվում են LED ցուցիչներում, կարևոր դեր են խաղում էլեկտրական կապը պահպանելու և տաքացման կառավարման գործում: Այս մուտքագրված սխեմաները սովորաբար պարունակում են բարձր հաճախականությամբ FR4 հիմնամաս, ինչպես նաև մոտ 2 ունցիա կշռող պղնձե շերտեր: Այս համադրությունը օգնում է պահպանել ազդանշանի ամբողջականությունը՝ անհրաժեշտ ժամանակակից էկրանների հարուստ 16-բիթանոց գունային խորությունների համար: Ջերմային կառավարման համար արտադրողները հաճախ ներառում են ալյումինե սերունդներ, որոնք կարող են տաքությունը ցրել մոտ 15 վատտ քառակուսի սանտիմետրի չափով: Երբ ակտիվ սառեցման լուծումների հետ զուգակցվում է, այլ ոչ թե պասիվ մեթոդներին հիմնվելով, շահագործման ջերմաստիճանը նվազում է մոտ 40%-ով, ինչը նշանակում է, որ այս ցուցիչները սովորաբար ավելի քան 70 հազար ժամ են տևում փոխարինում պահանջվելուց առաջ: Եվ նույնիսկ ներդրված է անվտանգության ապահովման սխեմատիկա՝ ապահովելու համար անընդհատ աշխատանքը, որը երաշխավորում է, որ պիքսելների անսարքությունները իրական կիրառման մեջ մնում են անհավանական հազվադեպ՝ պիքսելների տասնհազարից մեկից պակաս:

Քայլ առ քայլ LED էկրանի արտադրման գործընթաց

Վաֆլի արտադրություն՝ LED չիպերի արտադրության հիմքը

Արտադրության գործընթացը սկսվում է կիսահաղորդչային սաֆիրի կամ սիլիցիումե վաֆլների օգտագործմամբ, որոնք սովորաբար 4-8 դյույմ տրամագծով են: Այս վաֆլները պետք է լինեն ահռելի հարթ՝ գրեթե ատոմային հարթությամբ փոլիրովկայից հետո: Հետագայում կիրառվում է լուսագրաֆիկան՝ համատեղված քիմիական քայքայման մեթոդների հետ, որոնք ստեղծում են մանր պիքսելային կառուցվածքներ մակերևույթին: Այս փուլը հիմնականում սահմանում է ինչպես օպտիկական, այնպես էլ էլեկտրական հատկությունների հիմքը հետագայում: 2023 թվականի նյութերի գիտության վերջերս հրապարակված մի հոդվածի հետազոտությունները հետաքրքիր բան են հայտնաբերել. երբ վաֆլի մակերևույթի շեղումը 5 նանոմետրից պակաս է, այն իրականում 18 տոկոսով ավելի լավ լուսային արդյունավետություն է ապահովում համեմատած ավելի խոսուն մակերևույթների հետ:

Էպիտաքսիալ աճը և լցումը LED-ների արդյունավետության համար

Բյուրեղային շերտերի աճի գործընթացը՝ օգտագործելով մետաղաօրգանական քիմիական գոլորշու նստեցում (MOCVD), սովորաբար տեղի է ունենում շատ բարձր ջերմաստիճաններում՝ մոտ 1000 աստիճան Ցելսիուսից մինչև մոտ 1200 աստիճան: Այս պայմաններում առաջանում են անհրաժեշտ p-n անցումներ, որոնք թույլ են տալիս էլեկտրալուսարձակում: Երբ խոսքը գալիս է ճշգրիտ գույնը վերահսկելու մասին, արտադրողները արտադրության ընթացքում զգույշ կերպով ներմուծում են հատուկ տարրեր: Կապույտ լույսի արտադրման համար հաճախ օգտագործվում է մագնեզիումը, իսկ ուլտրամանուշակագույն տարբերակների համար ավելի լավ է աշխատում բերիլիումը: Այս զգույշ ավելացումը օգնում է պահպանել ալիքի երկարության ճշգրտությունը՝ սովորաբար ±2 նանոմետրի սահմաններում: Վերջերս բազմաքվանտային հորերի կառուցվածքների բարելավումները հնարավորություն են տվել ավելի հեռու առաջ գնալ: Որոշ լաբորատոր մոդելներ այժմ հասնում են 220 լյումեն/վատտ արդյունավետության՝ համաձայն անցյալ տարվա «Կիսահաղորդիչների արտադրություն» զեկույցի:

Չիպերի խորանարդիկներով բաժանում, փորձարկում և աղբարկղերի բաժանում՝ կայուն աշխատանքի համար

Էպիտաքսիալ աճից հետո վաֆլները կտրվում են առանձին LED չիփերի (0.1–2.0 մմ²)՝ օգտագործելով ադամանդե ծայրամասեր: Յուրաքանչյուր չիփ ավտոմատ ստուգման է ենթարկվում՝

- Լուսային համազանգվածություն (±5% թույլատրելի շեղում)

- Ուղղակի լարում (2.8Վ – 3.4Վ միջակայք)

- Գունային կոորդինատներ (ΔE < 0.005՝ caբարձրորակ խմբերի համար)

Մեքենայական տեսողության ուղղորդմամբ տարաների հավաքումը հասնում է 98.7% արտադրողականության՝ ապահովելով հետևողականություն արտադրական խմբաքանակների միջև (2023 թվականի արդյունաբերության չափանիշներ):

Ստեղծված մոնտաժման տեխնոլոգիա (SMT) LED դիսփլեի հավաքման ընթացքում

Ռոբոտային pick-and-place համակարգերը LED չիփերը տեղադրում են տպագրված հարթակների վրա՝ ավելի քան 30,000 կոմպոնենտ ժամում արագությամբ: Reflow փոխադրման ընթացքում ստեղծվում են միավորումներ՝ ենթա-10 մկմ ճշգրտությամբ, իսկ 3D SPI (փոխադրման հետազոտություն) հայտնաբերում է սխալներ՝ 15 մկմ թույլատրելի սահմաններում: SMT ավտոմատացումը 40%-ով կրճատում է հավաքման ծախսերը ձեռքով միացման մեթոդների համեմատ (2024 թ. արտադրության վերլուծություն):

Մոդուլային LED դիսփլեի վահանակների հավաքում առևտրային օգտագործման համար

Մոդուլային կառուցում և պիքսելային քայլի համար համապատասխան դիտարկումներ LED դիսփլեի դասավորության մեջ

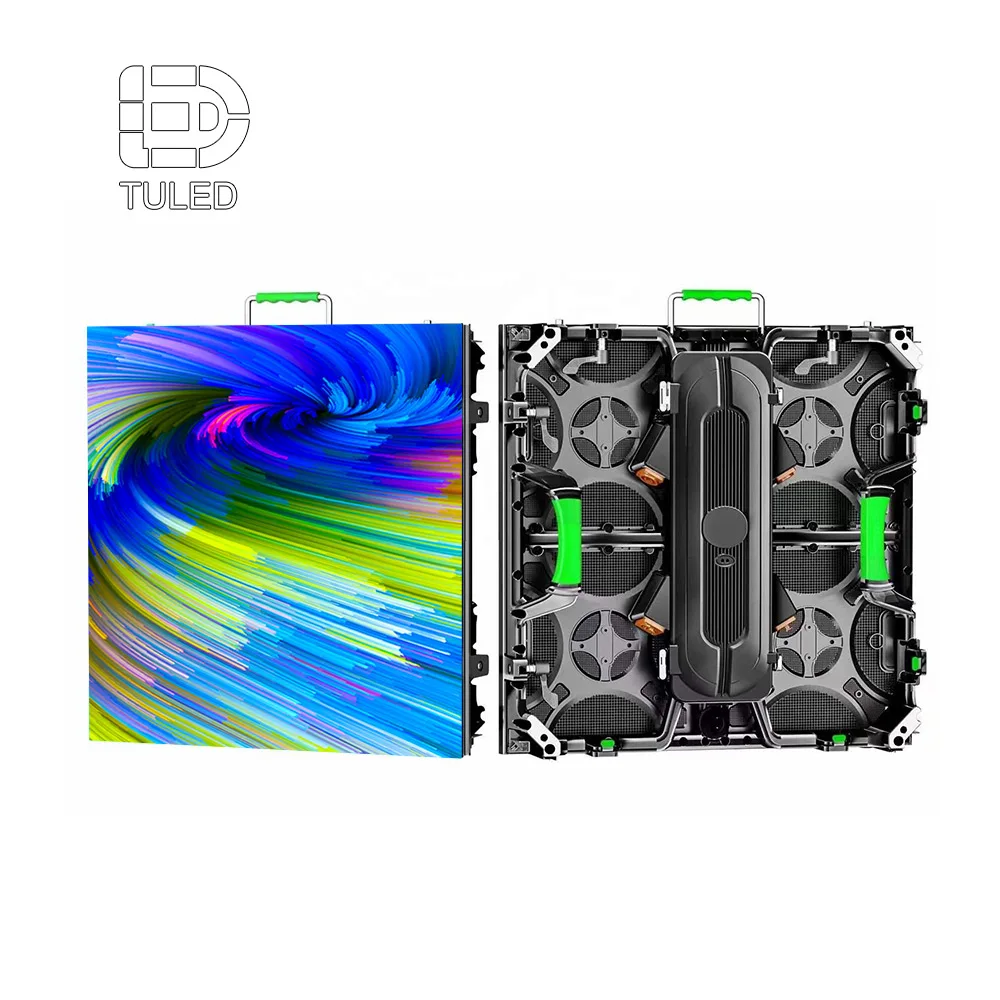

Առևտրային ամենաշատը LED էկրանները կառուցված են օգտագործելով մոդուլային վահանակներ, սովորաբար մոտ 500 մմ-ից 500 մմ-ից մինչև 1000 մմ-ից 1000 մմ չափսերով, որոնք իրար հետ հարթ կերպով են միանում: «Պիքսելային քայլ» տերմինը նկարագրում է, թե ինչ հեռավորության վրա են գտնվում առանձին LED-ները՝ մեկը մյուսից, և սովորաբար տատանվում է մոտ 1,5 մմ-ից մինչև 10 մմ: Այս չափումը հիմնականում երկու բան է ցույց տալիս. նկարի ուղղությունը և դիտորդի հեռավորությունը, որտեղ նա կարող է պարզորոշ տեսնել պատկերը: Շատ փոքր պիքսելային քայլ ունեցող ցուցադրումները, 2,5 մմ-ից ցածր ցուցանիշները, լավագույն ձևով աշխատում են, երբ դիտորդները գտնվում են դրանց կողքին, օրինակ՝ կառավարման կենտրոններում կամ հեռուստաընկերություններում: Ընդ որում, ավելի մեծ պիքսելային քայլ ունեցող ցուցադրումները ավելի լավ են համատեղվում գնի և արդյունավետության հետ այն վայրերում, որտեղ դիտորդները հեռվից են դիտում, ինչպես օրինակ՝ սպորտային արենաներում կամ համերգների վայրերում:

Կաբինետի ինտեգրում և սնուցման բաշխում խոշոր մասշտաբի LED համակարգերում

Ժամանակակից ալյումինե համաձուլվածքի կաբինետները պարունակում են բոլոր անհրաժեշտ բաղադրիչները՝ ներառյալ մոդուլային սալիկները, սնուցման աղբյուրները, մշակման միավորները և սառեցման մեխանիզմները: 960 մմ x 960 մմ չափսերով կաբինետների մեծ մասը կարող է տեղավորել 8-ից 12 սալիկներ, միաժամանակ շահագործման ընթացքում աղմուկը պահելով 65 դեցիբելից ցածր: Նշանավորելի է մի խելացի հատկանիշ՝ զուգահեռ սնուցման շղթայի կառուցվածքը, որը թույլ է տալիս տեխնիկներին սպասարկման աշխատանքներ իրականացնել համակարգի մասերի վրա՝ ամբողջ համակարգը ամբողջովին անջատելու անհրաժեշտություն չունենալով, ինչը գործնականում այս համակարգերին շատ ավելի հուսալի է դարձնում: Ջերմությունը կառավարելու հարցում նորագույն մոդելները օգտագործում են առաջադեմ ջերմային լուծումներ, որոնք, ըստ 2024 թվականի վերջերս հրապարակված հետազոտությունների, ջերմության ցրման արագությունը բարձրացնում են մոտ 15-ից 25 տոկոսով: Այս բարելավումը թարգմանվում է ավելի երկար կյանք ունեցող բաղադրիչների, և որոշ զեկույցներ նշում են, որ բաղադրիչների կյանքի տևողությունը կարող է երկարել մինչև 30 տոկոսով:

Բարակ պիտչի LED-ների հավասարակշռումը արդյունավետ արժեքի հետ իրական կիրառություններում

0,9 մմ թեքություն ունեցող մոդուլները տալիս են հիանալի 4K պարզություն մոտավորապես 3 մետր հեռավորությունից դիտելիս, սակայն ճիշտն ասած՝ 1200 դոլար մեկ քառակուսի մետրի համար մեծամասնության համար դրանք գումարատու են: Այդ իսկ պատճառով 2024 թվականի վերջին Display Economics զեկույցի համաձայն՝ ընկերությունների շուրջ 78%-ը նախընտրում է հիբրիդային կառույցներ: Դրանք օգտագործում են բարձր լուսանկարչականություն ունեցող P2.5-ից P3 մինչև P4-P6 տիրույթի մոդուլներ, որտեղ մարդիկ անմիջապես նայում են էկրաններին, իսկ ավելի էժան P4-P6 վահանակները օգտագործում են անկյուններում և կողմնային մասերում: Այս մոտեցումը կրճատում է ծախսերը մոտ 40%-ով՝ առանց նկարի որակի մեջ տարբերություն նկատելու: Եվ հետաքրքիր է, որ այս ծախսերի կրճատման հնարքը այժմ դարձել է բավականին ստանդարտ և հանդիպում է թվային նշանների տեղադրումների մոտ երկու երրորդում՝ խանութներում և տրանսպորտային հանգույցներում:

Ժամանակակից LED էկրանների շարժիչ էլեկտրոնիկան և կառավարման համակարգերը

Ինչպես են վարորդի IC-ները կարգավորում LED պիքսելների պայծառությունն ու գունային ճշգրտությունը

Ժամանակակից էկրանների վարորդի IC-ները յուրաքանչյուր ենթապիքսելին ուղարկում են հաստատուն հոսանք, ինչը օգնում է խոչընդոտել լարման փոփոխություններին և ջերմաստիճանի տատանումներին, որոնք կարող են խանգարել գույներին: Այս միկրոսխեմաները նաև բավականին արագ են աշխատում՝ մշակելով 25 ՄՀց-ի շուրջ սիգնալներ և աջակցելով 16 բիթանոց սերիական գունային սանդղակին: Դա նշանակում է, որ նրանք կարող են ստեղծել մոտ 281 տրիլիոն տարբեր գունային համադրություններ, որոնք էկրաններին տալիս են հարուստ վիզուալ որակ: Ամենակարևորն այն է, որ ներդրված ավտոկալիբրացիան ապահովում է գույների ճիշտ տեսքը նույնիսկ մի քանի տարի օգտագործման ընթացքում: Արդյունաբերական ստանդարտները սա չափում են Delta E-ով՝ 3-ից ցածր, ինչը հիմնականում նշանակում է, որ ցանկացած մարդ չի նկատի գունային ճշգրտության շեղում էկրանի ամբողջ կյանքի ընթացքում, որը հաճախ տևում է 50,000 ավելի շահագործման ժամերից ավելի:

Սիգնալի մշակում և թարմացման հաճախականություններ բարձր կարողություններով LED էկրաններում

Լավագույն LED ցուցիչները մշակում են 12G-SDI սիգնալներ 3840 Հց-ից բարձր թարմացման հաճախականությամբ՝ վերացնելով շարժման անթույլատրելիությունը արագ շարժվող պարունակության մեջ: Ժամանակային դիթերինգը բարձրացնում է ընկալվող բիթի խորությունը՝ առանց մեծացնելու շառավղային պահանջները: Բաշխված մշակման ճարտարապետությունները սինքրոնացնում են 2000-ից ավելի մոդուլներ 0,01°-ից պակաս ժամային շեղումով՝ ապահովելով անթերի համատեղում ընդարձակ տեսապատերաներում:

Որոշակի լուծումների փնտրտուք թարմացման հաճախականության և էներգասպառումների միջև

4K ցուցիչում 33 միլիոն անհատապես կառավարվող LED-ների աջակցումը ներկայացնում է զգալի էներգային մարտահրավերներ: Ճարտարագետները դրանք լուծում են երեք հիմնական մոտեցումներով.

- Դինամիկ լարման կարգավորում, որը նվազեցնում է էներգասպառումը ակտիվությունից դուրս գտնվող էկրանի տիրույթներում

- Ենթա-պիքսելային պատկերացույցի տեխնիկա, որը պահպանում է ընկալվող սրությունը ֆիզիկական LED-ների 25% պակաս քանակով

- Հիբրիդային էներգամատակարարման տոպոլոգիաներ, որոնք միավորում են կենտրոնացված և բաշխված կարգավորումներ

Այս նորարարությունները հնարավորություն են տալիս 2,5 մմ քայլով էկրաններին աշխատել 800 նիտ լուսարձակմամբ՝ սպառելով 450 Վտ/մ²-ից պակաս՝ 40 %-ով բարելավելով նախորդ նախագծերի ցուցանիշները (2023 թ. էկրանի ինժեներական ստանդարտներ):

Հաճախ տրամադրվող հարցեր

Ի՞նչ է էլեկտրալուսարձակումը LED տեխնոլոգիայում:

Էլեկտրալուսարձակումը այն սկզբունքն է, երբ կիսահաղորդչային նյութերը էլեկտրականություն անցնելիս արձակում են լույս, ինչը հնարավորություն է տալիս ցուցադրման յուրաքանչյուր LED-ին առանձին լույս արտադրել առանձին ետևի լուսավորություն առանց:

Ինչպե՞ս են աշխատում RGB ենթապիքսելները LED էկրաններում:

LED էկրանների RGB ենթապիքսելները կարմիր, կանաչ և կապույտ լույսերը միավորում են տարբեր ինտենսիվությամբ՝ ստեղծելով գույների լայն սպեկտր և հնարավորություն տալիս 16,7 միլիոն գունային տարբերակներ ստեղծել:

Ինչո՞ւ են GaN-ն և InGaN-ն կարևոր LED էկրաններում:

GaN-ն և InGaN-ն կիսահաղորդչային կարևոր նյութեր են, որոնք ապահովում են ճշգրիտ ալիքային երկարության վերահսկում, գերազանց ջերմային կայունություն և երկար շահագործման ընթացք LED էկրաններում:

Որո՞նք են LED էկրանների առավելությունները LCD և OLED-ի նկատմամբ

LED էկրանները գերազանցում են LCD և OLED էկրաններին՝ առաջարկելով բարձր պայծառություն, հակադրություն, էներգաարդյունավետություն և ավելի երկար ծառայողական սպասում, առանց OLED-ներին բնորոշ այրման ռիսկի:

Ինչպե՞ս է պիքսելի քայլը ազդում LED ցուցադրության որակի վրա:

Պիքսելների միջև հեռավորությունը որոշում է նկարի սրությունն ու օպտիմալ դիտման հեռավորությունը. փոքր հեռավորությունները հարմար են մոտիկ դիտման համար, իսկ մեծ հեռավորությունները՝ հեռավոր դիտման համար:

Ի՞նչ դեր են խաղում վարորդի IC-ները LED էկրաններում:

Վարորդի IC-ները կարգավորում են հոսանքը յուրաքանչյուր ենթապիքսելի մեջ՝ ապահովելով գույների ճշգրիտ և համապատասխան պայծառություն՝ լարման տատանումների և ջերմաստիճանի փոփոխությունների դեպքում: