Componente de bază și arhitectura sistemului pentru panouri de afișaj LED

Componentele principale ale sistemului de afișaj LED: Module, circuite integrate de comandă, surse de alimentare și plăci de control

Ecranele LED moderne funcționează precum niște ecosisteme complexe, formate din patru componente principale care lucrează împreună. Modulele LED sunt în esență elementele de bază, conținând acele diode mici RGB grupate pentru a crea fiecare pixel pe care îl vedem pe ecran. Cipurile driver realizează și ele o sarcină remarcabilă: controlează cantitatea de electricitate care ajunge la fiecare diodă cu o acuratețe de aproximativ 2%, permițând producătorilor să regleze precis nivelul de luminozitate folosind tehnologia cunoscută sub numele de PWM. Atunci când avem de-a face cu instalații mari care cuprind mai multe panouri, sursele distribuite de alimentare devin esențiale pentru menținerea unei funcționări continue, în ciuda scăderilor de tensiune pe parcurs. Și nu trebuie uitate plăcile de control — acestea funcționează aproape ca un creier al întregului sistem, preluând toate semnalele de intrare și coordonând ratele de reîmprospătare la viteze sub 1 milisecundă, astfel încât videoclipurile să ruleze fără artefacte sau distorsiuni deranjante.

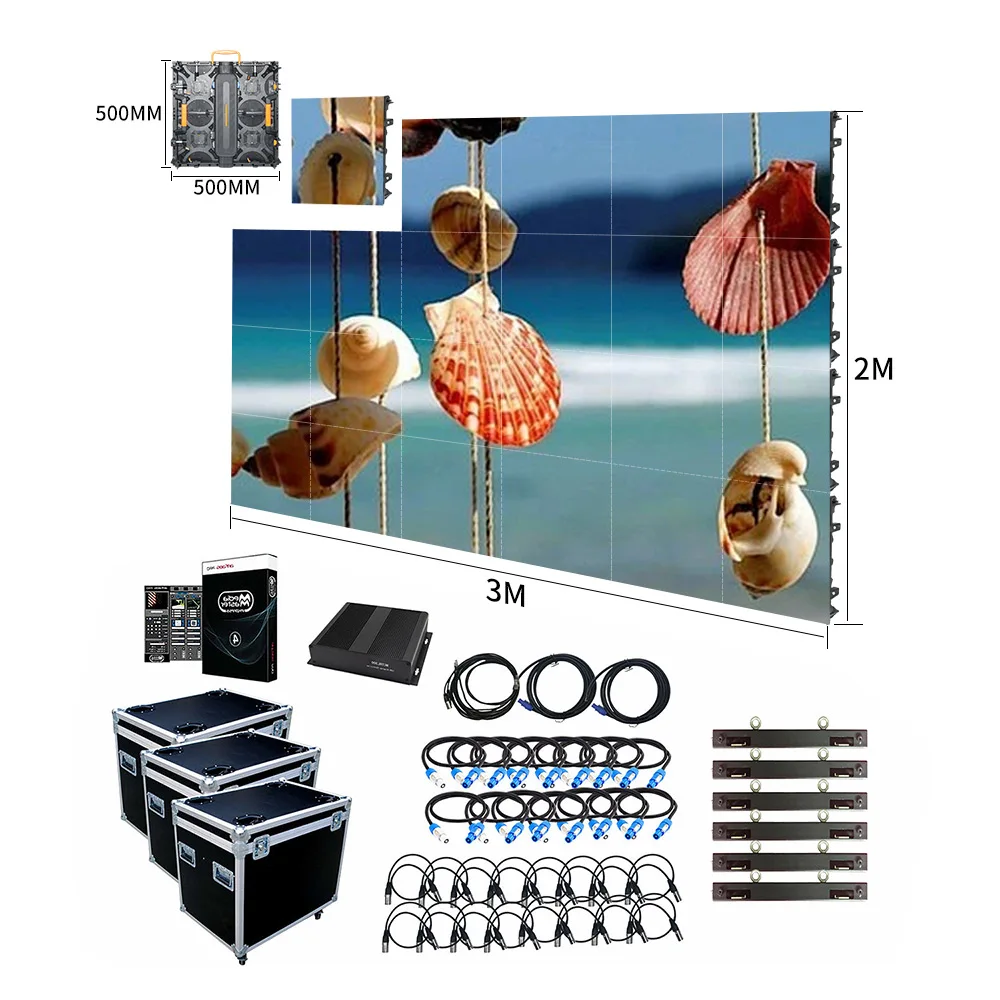

Structura modulului LED și integrarea în grile mai mari de panouri

Dimensiunea standard pentru modulele LED este de obicei în jur de 320x160 mm sau 320x320 mm, ceea ce face posibilă realizarea ecranelor video mari în zilele noastre, cu instalații care depășesc frecvent 1000 de metri pătrați. Construcția are mai multe straturi. În primul rând, există acele matrice SMD sau COB LED montate pe plăci FR-4. Apoi urmează stratul de silicon care protejează împotriva prafului și umidității. Și să nu uităm de pioanele mici de aliniere, cu toleranța extrem de precisă de ±0,1 mm, care asigură potrivirea perfectă fără goluri. Majoritatea sistemelor vin cu conectori integrați, astfel încât instalarea nu durează la nesfârșit, uneori doar câteva minute per panou. Există, de asemenea, un software destul de inteligent care funcționează în fundal, numit algoritmi de difuzie a erorilor, care corectează diferențele minore de culoare și luminozitate acolo unde se întâlnesc panourile. Placa din aluminiu de la spate are un rol dublu: ajută la disiparea căldurii, astfel încât temperatura internă să rămână sub 85 de grade Celsius, ceea ce înseamnă că aceste ecrane pot dura mult mai mult înainte de a necesita piese de schimb.

Structura și Compoziția Panourilor LED, Inclusiv Substraturi de Circuit și Carcase Protectoare

Panourile LED comerciale utilizează o construcție robustă, cu mai multe straturi, pentru durabilitate:

| Stratificare | Material | Funcție | Grosime |

|---|---|---|---|

| Față | Alte produse | Etanșare la intemperii, anti-reflex, blocare UV | 3–5 mm |

| CIRCUIT | Epoxid FR-4 | Dirijarea semnalului | 1,6 mm |

| Matrice LED | PCB din aluminiu | Gestionarea termică | 2 MM |

| Suport | Oțel acoperit cu pulbere | Suport structural | 1–3 mm |

Panourile proiectate pentru utilizare în aer liber sunt echipate în mod tipic cu sigilări IP65, precum și cu acoperăminte protectoare aplicate pe circuitele integrate ale driverului, ceea ce ajută la menținerea umidității la distanță—un factor care adesea duce la defecte atunci când echipamentul este expus unor condiții dificile. Pentru gestionarea căldurii, producătorii folosesc substraturi din aluminiu de calitate aerospace, care conduc căldura la aproximativ 205 W/mK. Aceste materiale funcționează împreună cu canale de răcire special concepute pe partea din spate a panoului, reducând temperaturile de funcționare cu aproximativ 15 grade Celsius față de carcasele obișnuite. Această combinație permite o performanță fiabilă chiar și în condiții de funcționare continuă 24/7, unele unități putând dura până la 100.000 de ore înainte de a necesita înlocuire.

Tehnologii ale Modulelor LED: Compararea DIP, SMD și GOB pentru Diferite Aplicații

Compoziția de Bază a Ecranelor LED Utilizând Module DIP (Pachet cu Două Rânduri)

DIP înseamnă Dual In Line Package, iar aceste unități LED au diode mici cu două pini sigilate în interiorul unor capsule care sunt lipite direct pe plăcile de circuit imprimat. De asemenea, ele strălucesc foarte puternic, atingând aproximativ 8000 nits, ceea ce le face vizibile chiar și atunci când soarele este puternic. Construcția este destul de robustă, funcționând perfect fie că este ger de minus 30 de grade Celsius, fie că este cald ca la tigaie la 60 de grade. În plus, au o clasă de protecție IP65, astfel încât praful și apa nu le vor împiedica să-și facă treaba. Din acest motiv le vedem peste tot pe panourile publicitare mari de afară și pe semne montate pe autobuze sau trenuri. Dar există un dezavantaj. Deoarece fiecare pixel este distanțat între 10 și 40 de milimetri, calitatea imaginii nu este suficient de bună pentru vizualizarea de la distanță mică. Astfel, aceste lumini funcționează cel mai bine atunci când oamenii le privesc de la distanțe mari, unde detaliile nu sunt esențiale.

Panouri SMD LED pentru aplicații interioare cu densitate mare

Tehnologia SMD împachetează LED-uri mici de culoare roșie, verde și albastră în carcase mici cu dimensiuni între 2 și 5 milimetri pătrați. Aceste componente miniaturizate creează un pas al pixelilor extrem de fin, cuprins între 0,9 mm și 2,5 mm. Ce înseamnă acest lucru? Pentru spectatori aflați la aproximativ trei metri distanță, aceste ecrane oferă o rezoluție 4K reală. În plus, datorită cipurilor sofisticate de reglare a curentului, redarea culorii atinge aproximativ 95% din standardul NTSC. Desigur, panourile SMD nu sunt concepute pentru utilizare în exterior, deoarece strălucirea lor maximă este de 1.500–2.500 nits. Dar în interiorul clădirilor? Sunt peste tot acum. Studiourile de difuzare se bazează pe ele, magazinele le folosesc pentru prezentarea produselor, iar companiile le montează în holurile lor ca să facă o impresie puternică.

Tehnologia GOB (Glue on Board) – Sporirea durabilității și rezistenței la umiditate

Tehnologia GOB îmbunătățește performanța în aer liber prin aplicarea unui strat special de rășină epoxidică transparentă pe modulele LED, de obicei cu o grosime între 0,3 și 0,5 milimetri. Testele de teren arată că aceasta poate rezista la impacturi de trei ori mai bine decât soluțiile standard, conform standardului ASTM D2794. În zonele din apropierea coastei, unde umiditatea este mereu o problemă, ratele de defectare scad cu aproximativ 70%. Ce face ca GOB să se remarce? Indicele său de refracție variază între 1,49 și 1,53, permițând trecerea a aproximativ 90% din lumină fără distorsiuni. Acoperirile tradiționale creează adesea efecte neplăcute de lentilă mică care afectează calitatea iluminatului, dar GOB nu are deloc această problemă.

Studiu de caz: Adoptarea tehnologiei SMD versus GOB în afișajele exterioare de stadion

O analiză din 2023 a celor 15 modernizări de stadionuri a demonstrat superioritatea tehnologiei GOB în condiții solicitante:

| Metric | Module SMD | Module GOB |

|---|---|---|

| Rata anuală de defectare | 12.7% | 3.2% |

| Pierdere de luminozitate | 15%/an | 5%/an |

| Costul de întreținere | 74 $/m² | 22 $/m² |

În ciuda unei investiții inițiale cu 28% mai mari, panourile GOB au atins un cost total de proprietate mai scăzut în 11 luni datorită întreținerii reduse și duratei mai lungi de funcționare.

Culoare și calitate a imaginii: Amestecarea RGB, organizarea pixelilor și adâncimea culorii

Amestecarea culorilor RGB în ecranele LED pentru redarea completă a spectrului de imagini

Ecranele LED de astăzi pot crea imagini incredibil de realiste datorită unui sistem numit sistemul aditiv RGB. În esență, aceste ecrane amestecă subpixeli roșii, verzi și albaștri la diferite niveluri de strălucire, de la zero la 255 pe fiecare canal de culoare. Această capacitate de amestec le permite să afișeze aproximativ 16,7 milioane de culori distincte, ceea ce acoperă aproximativ 92 la sută din ceea ce putem vedea efectiv în modelele high-end. Aceste ecrane de top ating chiar același gamut de culori ca standardul DCI-P3 utilizat în cinematografe. Când roșu, verde și albastru sunt setați la maximul de strălucire simultan, rezultatul este o lumină albă pură. Totuși, obținerea echilibrului corect între aceste culori este foarte importantă, mai ales când se creează conținut pentru emisiuni TV sau filme, unde acuratețea culorii face toată diferența.

Organizarea pixelilor LED și structura rețelei care determină uniformitatea afișajului

Calitatea imaginilor depinde într-adevăr de modul în care aceste pixeli RGB sunt asamblați și aranjați într-un mod uniform. Luați, de exemplu, un perete LED standard 4K cu dimensiunile de 3840 pe 2160 de pixeli – vorbim de aproximativ 8,3 milioane de pixeli separați care necesită control individual. În prezent, o bună fabricare menține diferențele de luminozitate sub 5% pe întregul ecran, datorită unor tehnici mai bune de spațiere și a unor configurații mai inteligente ale circuitelor. Distanța dintre pixeli (pixel pitch) face tot diferența. Ecranele moderne au adesea distanțe mult mai mici, cum ar fi 0,9 mm, comparativ cu panourile publicitare vechi care foloseau valori apropiate de 10 mm. Acest lucru este important deoarece spectatorii pot sta chiar lângă ecran – uneori la doar trei metri distanță – și totuși pot vedea imagini continue și netede, fără nicio despărțitură vizibilă între pixeli.

Adâncimea culorii și acuratețea imaginii în panourile LED prin reglarea precisă a curentului

Afisajele care oferă o adâncime de culoare de 12 biți reușesc să afișeze aproximativ 68,7 miliarde de culori diferite, deoarece controlează curentul electric care trece prin fiecare LED cu o precizie destul de mare, de aproximativ plus sau minus 1%. Această reglare fină elimină apariția acelor benzi de culoare deranjante atunci când se privesc tranziții uniforme între nuanțe. Profesioniștii din domeniul medical se bazează pe aceasta în examinarea imaginilor, unde chiar și cele mai mici variații de culoare contează, iar designerii grafici care lucrează la proiecte de înaltă calitate au nevoie și ei de această precizie. Atunci când sunt calibrate corespunzător, aceste ecrane ating ceea ce se numește Delta E sub 3, astfel încât orice diferență de culoare față de monitoarele de referință standard devine practic invizibilă în condiții reale de studio. Cei mai experimentați profesioniști nu ar observa nimic neobișnuit, chiar dacă s-ar uita la ele timp de ore întregi.

Tendință: Evoluții ale tehnologiilor Mini-LED și Micro-LED care permit o gradare mai fină a culorilor

Dimensiunea mică a micro-LED-urilor, de doar 50 de micrometri, le face mult mai mici decât LED-urile obișnuite, care au aproximativ 200 de micrometri. Această miniaturizare permite densități ale afișajului de până la 2500 de pixeli pe inch, cu niveluri de luminozitate între 0,01 și 2000 de nituri. Când combinăm aceste LED-uri mici cu tehnologia punctelor cuantice și 16 mii de zone de atenuare locală distribuite pe ecran, ce obținem? Un raport de contrast impresionant de 20.000 la 1 și o redare a culorilor care acoperă 110% din spectrul NTSC. Acest lucru depășește tehnologia OLED cu aproximativ 40%. Pentru persoanele care urmăresc conținut HDR, acest lucru înseamnă că umbrele mai întunecate par mai bine definite, fără a pierde adâncimea. Deși este încă relativ nouă, mulți experți cred că micro-LED-ul va deveni în cele din urmă standardul pentru afișajele premium datorită acestor capacități impresionante.

Indicatori de performanță vizuală: Pasul pixelului, luminozitatea, rata de reîmprospătare și controlul PWM

Pasul pixelului și impactul său asupra rezoluției și distanței optime de vizionare

Pasul pixelului – distanța dintre centrele LED-urilor adiacente, exprimată în milimetri – influențează direct rezoluția și distanța de vizionare optimă. Pasi mai mici oferă imagini mai clare pentru aplicații la distanță scurtă:

| Distanța de vizionare | Pasul pixelilor recomandat | Exemple de utilizare |

|---|---|---|

| < 2,5 metri | ≤ P1.5 | Studiouri de televiziune, comerț cu amănuntul |

| 2,5–10 metri | P2.5–P6 | Săli de conferință, holuri |

| 10 metri | ≥ P8 | Stadioane, panouri publicitare |

Pentru medii intensive în ceea ce privește detaliile, cum ar fi sălile de control, pasul P1.5 sau mai fin asigură claritate fără separarea pixelilor.

Standarde de strălucire (Nits) pentru medii interioare și exterioare

Cerințele de luminozitate variază semnificativ în funcție de context:

- Interior : 800–1.500 nituri echilibrează vizibilitatea cu strălucirea

- În aer liber : 5.000–10.000+ nituri contracarează lumina directă a soarelui

O luminozitate mai mare crește consumul de energie, astfel că proiectanții optimizează randamentul folosind calibrare optică și senzori de lumină ambientală pentru a menține eficiența fără a compromite vizibilitatea.

Rata de reîmprospătare și netezimea vizuală în ecranele LED pentru conținut rapid

Panourile LED de înaltă performanță susțin rate de reîmprospătare de 1.920–3.840 Hz, eliminând estomparea mișcării în timpul conținutului rapid, cum ar fi transmisiile sportive sau competițiile de esports. Cu timpi de răspuns sub 1 ms, aceste ecrane previn efectul de fantomă și asigură tranziții clare ale imaginii – esențiale pentru locațiile evenimentelor live și arenele de jocuri video, unde precizia vizuală influențează experiența spectatorilor.

Controlul tensiunii și gestionarea luminozității utilizând tehnici PWM

Modularea în durată a impulsurilor (PWM) controlează luminozitatea prin comutarea rapidă a LED-urilor între stările pornit și oprit, fără a reduce tensiunea, păstrând astfel acuratețea culorii la diferite niveluri de întunecare. Totuși, PWM-ul cu frecvență joasă (<1.000 Hz) poate introduce un efect de clipire perceptibil, mai ales în câmpul vizual periferic.

Paradoxul industriei: Rata mare de reîmprospătare vs. Clipire indusă de PWM în modurile cu luminozitate scăzută

Chiar dacă aceste rate impresionante de reîmprospătare depășesc 3000 Hz, o cercetare realizată de DisplayMate în 2023 a arătat un fenomen interesant la niveluri scăzute de luminozitate. Aproximativ șapte din zece ecrane LED au prezentat o clipire vizibilă atunci când au fost setate sub 20% luminozitate, datorită modului în care sistemele lor PWM funcționează cu cicluri fixe de lucru. Cu toate acestea, marii producători au început să rezolve această problemă. Ei implementează ajustări inteligente ale PWM care se modifică în funcție de ceea ce se întâmplă în jurul ecranului și de tipul conținutului afișat. Aceasta ajută la reducerea efectului de clipire fără ca întunecarea să pară sacadată sau nefirescă pentru privitor.

Întrebări frecvente

Care sunt componentele principale ale panourilor de afișaj LED?

Componentele principale includ module LED, circuite integrate de comandă, surse de alimentare și plăci de control care lucrează împreună pentru a gestiona fluxul de electricitate, luminozitatea și redarea video.

Cum se compară diferitele tehnologii de module LED, cum ar fi DIP, SMD și GOB?

Modulele DIP oferă o luminozitate ridicată și durabilitate pentru utilizare în aer liber, dar o rezoluție mai scăzută. SMD oferă densitate ridicată și acuratețe a culorii pentru ecranele indoor, în timp ce GOB sporește durabilitatea și rezistența la umiditate prin un strat special de epoxid.

Ce factori afectează performanța vizuală a ecranelor LED?

Pasul pixelului, luminozitatea, rata de reîmprospătare și controlul PWM sunt factori cheie care determină rezoluția, vizibilitatea și fluiditatea conținutului în mișcare rapidă la ecranele LED.

Ce evoluții fac ca tehnologia micro-LED să fie promițătoare pentru ecranele premium?

Micro-LED-urile oferă densități de afișare mai mari, cu o luminozitate și rapoarte de contrast mai bune, depășind tehnologiile LED mai vechi și urmând să devină standard în ecranele de înaltă gamă.