Թափանցիկ LED էկրանների տեխնոլոգիայի հասկանալը

Ինչ է թափանցիկ LED էկրանը և ինչպես է աշխատում:

Շրջանցման LED էկրանները իրենց բնույթով էկրաններ են, որոնք թույլ են տալիս մարդկանց տեսնել նրանց միջով՝ միևնույն ժամանակ ցուցադրելով թվային տեղեկատվություն: Այս էկրանները աշխատում են միկրո-LED տեխնոլոգիայի շնորհիվ, որտեղ փոքրիկ լույսերը սովորաբար 3-ից 10 միլիմետր հեռավորության վրա են միմյանցից: Այս փոքրիկ LED կետերը տեղադրված են ապակիների կամ պոլիկարբոնատե թիթեղների նման թափանցիկ նյութերի վրա: Լույսը անցնում է այդ տարածումներով, որոնք գտնվում են իրական LED-ների միջև: Արդյունքում՝ այս էկրանները կարող են լինել մինչև 95% թափանցիկ, բայց նույնիսկ շատ պայծառ՝ մոտ 3000-ից 5000 նիտ, այնպես որ դրանք հստակ երևում են նույնիսկ արևոտ օրերին դրսում: Բավականի հետաքրքիր է, թե ինչպես են նրանք միաժամանակ կարողանում իրականացնել երկու ֆունկցիաները: Մարդիկ կարողանում են վայելել տարբեր շարժական նկարներ և տեղեկություններ առանց այն զգացողության, որ տեսադաշտը փակվել է կամ բնական լույսը նվազել է:

Կիրառման հիմնական ոլորտները ժամանակակից ճարտարապետության և մանրածախ վաճառքի միջավայրում

Բացատրելով թափանցիկ LED տեխնոլոգիան, ապակեպատերը և խանութների պատուհանները դառնում են մի բան, որը ամբողջովին նոր է: Այն, ինչ մենք տեսնում ենք հիմա, շենքեր են, որտեղ ճարտարապետները այդ ցուցիչները տեղադրել են արտաքին ապակու մեջ, միաձուլելով թվային արվեստը իրական ճարտարապետության հետ՝ պահպանելով բնական լույսի անցումը: Իսկապես գեղեցիկ բան է: Ռետայլ տարածքների համար բարձր թույլատրական թափանցիկ էկրանները թույլ են տալիս խանութներին ստեղծել AR ապրանքների ցուցադրություններ, որոնց հետ հաճախորդները կարող են անմիջապես փոխազդել: Որոշ խանութներ սկսել են նույնիսկ այս տեխնոլոգիան օգտագործել ապրանքների տարբերակները ցուցադրելու համար՝ կախված այն բանից, թե ինչ եղանակ է կամ հատուկ գործողություններ են ընթանում այդ պահին: 2023 թվականի հունվարին թողարկված զեկույցը թվային ցուցանակների մասին հայտնեց, որ առևտրի կենտրոններում այդ տեսակի ցուցիչների տեղադրումից հետո, հաճախորդները մոտ 40 տոկոսով ավելի երկար ժամանակ էին անցկացնում ապրանքների դիտման վրա և գնում էին այն ապրանքները, որոնք տեսնում էին այդ էկրաններում:

Լուսավորության և նկարի համաչափության մեջ առկա հարցերը

Շատ լավ են թվում թափանցիկ LED էկրանները, սակայն դրանք ունեն նաև լուրջ թերություններ: Երբ արտադրողները մեծացնում են թափանցիկությունը, մեկ դյույմում պիքսելների քանակը կտրուկ նվազում է: Վերցրեք, օրինակ, 8 մմ պիքսելային քայլ ունեցող էկրանները՝ դրանք սովորաբար դժվարանում են հասնել նույնիսկ մոտ 12K ուղղակի ստանդարտներին: Մեկ այլ խնդիր է պատկերի որակը՝ հատկապես պարզ արևոտ եղանակի դեպքում: Էկրանի որոշ մասեր կարող են սկսել մութնել, քանի որ տարբեր մոդուլների ջերմաստիճանները տարբեր են: Ponemon ինստիտուտը պարզել է, որ շրջապատող միջավայրի ջերմաստիճանը իրականում կարող է փոխել էկրանի գունային նախերական մոտ 12%-ով, ինչը նշանակում է, որ ընկերությունները պետք է բավականի բարդ լուծումներ ունենան, եթե ցանկանում են, որ այդ էկրանները անխափան աշխատեն ամբողջ օրվա ընթացքում առանց տեսանելի խնդիրների:

COB LED տեխնոլոգիայի հնարավորությունների և առավելությունների ուսումնասիրություն

Ինչ է COB LED-ը. ներկայացնելով չիպ-վրա-տախտակի (COB) տեխնոլոգիան

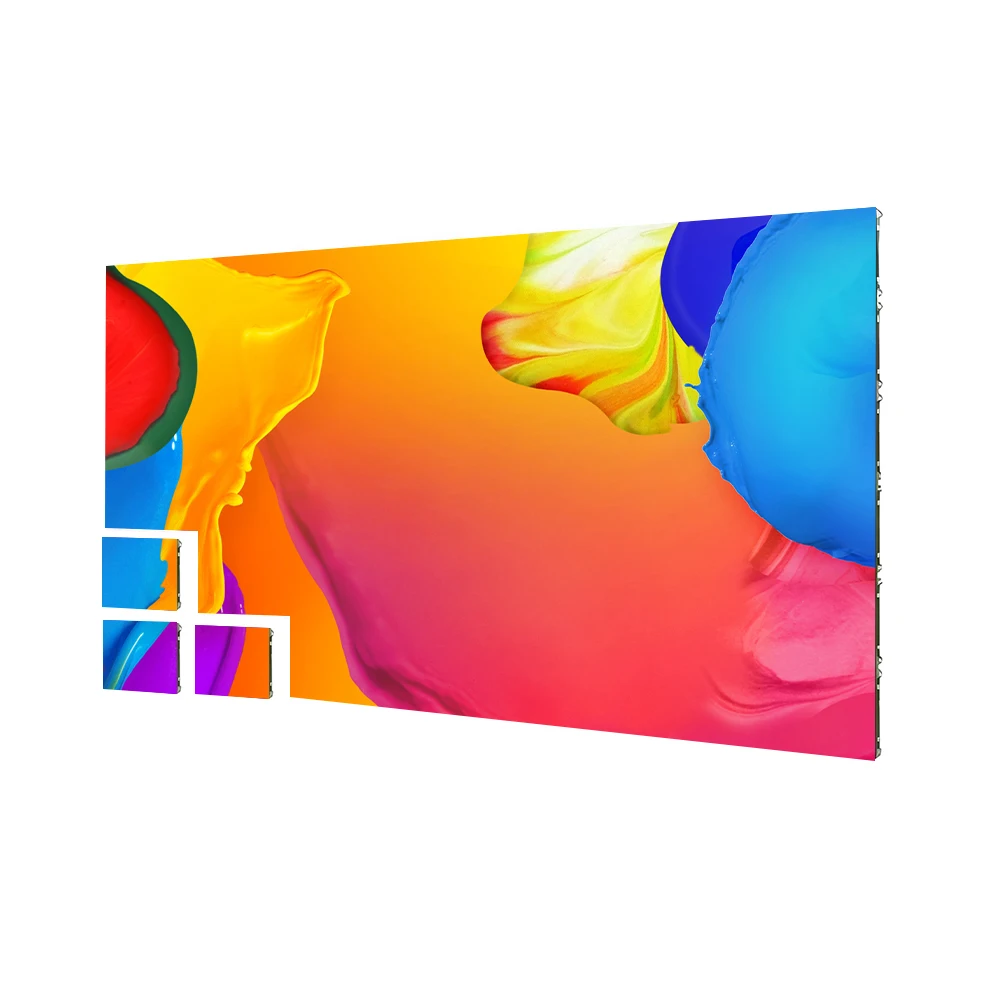

Chip on Board (COB) LED տեխնոլոգիան աշխատում է այնպես, որ մի քանի LED չիփեր ամրացվում են տպագրված ամփոփիչ վահանակին՝ սովորական Surface Mounted Device (SMD) LED-ներում տեսանելի առանձին պլաստմասսայե կոնտեյներների փոխարեն: Սա նշանակում է, որ լույսերի միջև գրեթե տեղ չի մնացել: Արդյունքում՝ ավելի հարթ լուսարձակող մակերես, որտեղ պիքսելները աչքին անտեսանելի են: Երբ արտադրողները բոլոր այս չիփերը ծածկում են մեկ մեծ պաշտպանական շերտով, ամբողջ համակարգը ավելի երկար է ծառայում և օպտիկական առումով ավելի լավ է աշխատում: Բացի այդ, բաղադրիչները ավելի քիչ են վնասվում, քանի որ շահագործման ընթացքում դրանց վրա ավելի քիչ ֆիզիկական լարվածություն է առաջանում: Շատ լուսավորության ընկերություններ սկսել են անցնել COB-ին՝ այդ առավելությունների շնորհիվ, հատկապես խոշոր մասշտաբային տեղադրումներ ստեղծելիս, երբ հուսալիությունը ամենակարևորն է:

Բարելավված պիքսելային հեռավորություն, գունային համապատասխանություն և էկրանի որակ

COB տեխնոլոգիան թույլ է տալիս իրականում փոքր պիքսելների միջակա հեռավորություն մինչև մոտ 0,6 մմ, ինչը հնարավորություն է տալիս ստանալ 4K որակ ավելի փոքր տեսապատի կարգավորումներում: Երբ համեմատում ենք ստանդարտ SMD էկրանների հետ, որտեղ գունային տարբերություններ կարող են տեղի ունենալ մոդուլից մոդուլ մեկ այլ գույնի, COB-ն ունի համապարփակ փաթեթավորման առավելություն, այնպես որ ամբողջ էկրանը ցույց է տալիս շատ ավելի քիչ գունային տարբերություն: Փորձարկումները ցույց են տվել, որ այդպիսի COB էկրանները պահում են իրենց սկզբնական գունային ճշգրտության մոտ 98%-ը մոտ 10,000 ժամ անընդհատ աշխատելուց հետո, ինչը գերազանցում է ստանդարտ SMD տարբերակներին մոտ 15%-ով: Այդպիսի համապարփակությունը շատ կարևոր է մասնագիտական էկրանների կարգավորման ժամանակ, որտեղ յուրաքանչյուր մանրամասն կարևոր է:

COB փաթեթավորման միջոցով բարելավված հուսալիություն և տևականություն

COB տիպի էկրանները չունեն այդ անհարմար բաց թողնված հաղորդալարերը կամ փողային միացումները, ինչը նշանակում է, որ դրանք մակերեսային մոնտաժի (SMD) մոդելների համեմատ մոտ 60% ավելի քիչ մեռած պիքսելներ են ունենում: Դրանք պատված են այս ահագին դիմացկուն ռազմական ստանդարտ էպօքսի խեժով, որը նրանց ապահովում է IP68 ջրամբարի դիմադրությամբ և կարող է դիմանալ տարբեր տեսակի ամբարձումներին՝ 8H մատիտի կարծրության թեստի ընթացքում: Այդ էկրանները դարձնում է դրանք իսկապես լավ ընտրություն այն տեղերի համար, որտեղ մարդիկ մշտապես անցնում են կամ դիպչում են նրանց: Երբ խոսքը վարը է ջերմաստիճանի սրտաճաշակների մասին, ջերմային շոկի թեստերը ցույց են տալիս, որ այդ էկրանները շարունակում են ճիշտ աշխատել, նույնիսկ երբ ջերմաստիճանը իջնում է մինչև մինուս 30 աստիճան Ցելսիուս կամ բարձրանում է մինչև այրող 85 աստիճան Ցելսիուս, իսկ նկարները մնում են պարզ առանց աղավաղման:

Էներգախնայողություն և բարձրակարգ ջերմային կառավարում

Երբ COB տեխնոլոգիան ջերմությունը անմիջապես փոխանցում է ալյումինե ստորակերպերին, իրականում աշխատանքային ջերմաստիճանը նվազում է մոտ 22 աստիճան Ցելսիուսով ստորև, քան այն, ինչ տեսնում ենք ավանդական SMD դիզայնների դեպքում: Այս բարելավված արդյունավետությունը նշանակում է, որ այս համակարգերը սպառում են մոտ 30 տոկոսով պակաս էներգիա, նույնիսկ այն բանից հետո, երբ դրանք արտադրում են 5000 նիտ լուսավորության մակարդակը: Արտադրողները նաև ավելացրել են մի քանի բավականի խելացի վարորդային շղթաներ, որոնք կրճատում են էներգիայի կորուստները ավելի մութ տեսարանների ընթացքում 30-ից մինչև 40 տոկոս: Սա հնարավոր է դարձնում, որ COB ցուցադրումները հնարավոր է համապատասխանեն ENERGY STAR պահանջներին՝ լույսի արտադրության անկում առանց կատարում:

Շուկայական միտումներ. SMD-ից COB LED ցուցադրումների փոխակերպում

Ինչու են առևտրային կիրառությունները ընդունում COB LED տեխնոլոգիան

Վարձու ցուցադրումները այսօր արագ տեղաշարժվում են սովորական SMD տեխնոլոգիայից դեպի COB LED լուծումներ: Ինչու՞: Ըստ AVCOM տվյալների 2025 թվականից, ընկերությունները 5 տարվա ընթացքում մոտ 55% խնայում են սպասարկման վրա, COB-ի դեպքում, ինչպես նաև այն ավելի լավ է դիմանում դժվարին պայմաններին: COB-ի դեպքում չկան բաց եղած փողային միացումներ, որոնք կարող են վնասվել խոնավությունից կամ անընդհատ օգտագործումից, ինչը մեծ նշանակություն ունի հիվանդանոցներում, դպրոցներում կամ մեծ կառավարման կենտրոններում անընդհատ աշխատող էկրանների համար, որտեղ կանգ առանց աշխատանքը պարտադիր է: Տվյալների համաձայն, այժմ մոտ կեսը (շուրջ 42%) կորպորատիվ տեսապատերի օգտագործում է COB տեխնոլոգիան: Շատ ընկերություններ նախընտրում են այն, քանի որ նրա մակերեսը ունի հարթ, մատնանշանակ տեսք, որը նվազեցնում է անհարմար արտացոլումները լուսավոր տարածքներում՝ առանց էկրանի ընդհանուր գունային տեսքի վրա ազդելու:

COB Օգտագործող Թվային Նշանների Եւ Ներքին Տեսապատերի Աճը

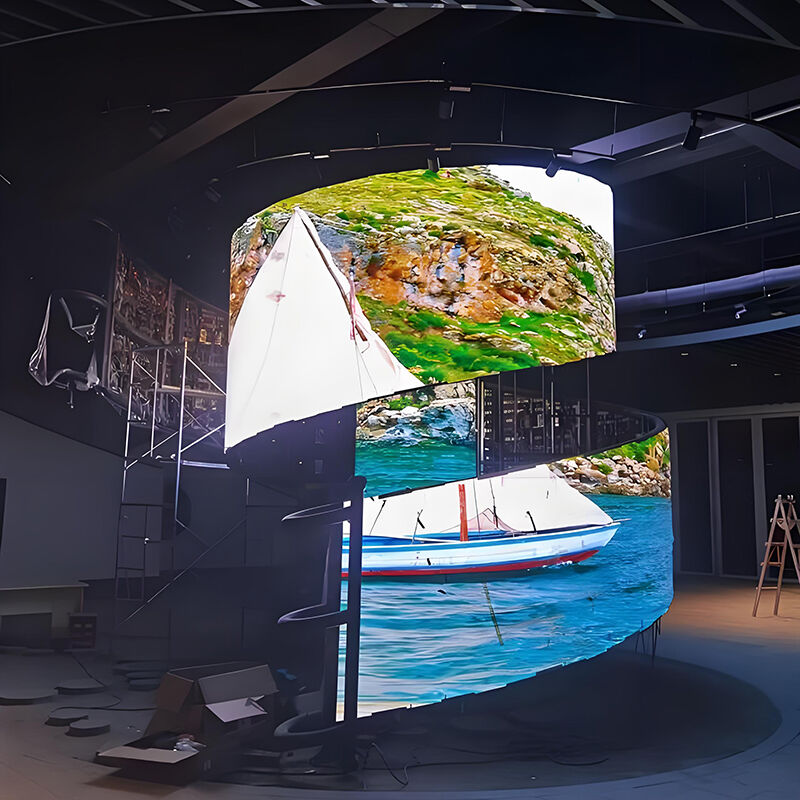

COB տեխնոլոգիան իրականում գերակշռում է նեղ պիքսելային հեռավորությունների շուկայում, ստանձնելով մոտ 35% տեղադրումներից, որտեղ պիքսելային հեռավորությունը ըստ Չենի 2025 թվականի հետազոտությունների ցածր է 1,5 մմ-ից: Խանութները այս տեխնոլոգիայի համար խելագարվում են, քանի որ այն ապահովում է այդքան հզոր լուսային ցուցանակները՝ 1,500 նիտներով, և նույնիսկ այդպես էլեկտրաէներգիայի սպառումը մնում է բավականաչափ հիմնավորված, որպեսզի ամենօրյա շահագործման ծախսերը հնարավոր լինի կառավարել: Վիրտուալ արտադրության համար էլ այն, ինչ առանձնացնում է COB-ն, այն է, թե ինչպես է նրա վրա գունային ներկայացումը համարվում կինոնման որոշիչ տեսք, որն անհրաժեշտ է ժամանակակից հեռուստասերիալների և ֆիլմերի համար: Ամեն տարի տեսնում ենք մոտ 25% ավելի շատ ստուդիաներ, որոնք անցնում են COB-ի, ինչպես հնարավոր է հեռուստատեսության արտադրության, այնպես էլ սովորական հեռարձակման կարիքների համար:

Միկրոմինիատյուրացում և Ապագային Տեխնոլոգիաների Ամրապնդում COB Էկրաններում

Վերջերս այդ համալիրների փաթեթավորման մեթոդների բարելավումները նվազեցրել են COB պիքսելների քայլը մինչև 0,9 մմ: Սա նշանակում է, որ հիմա մենք կարող ենք ստանալ 8K թուլաչափ, իսկ ավանդական SMD դիսպլեների համեմատ օգտագործել մոտ 30% պակաս էներգիա՝ ըստ AVCOM-ի 2025 թվականի հետազոտությունների: Առանձին պիքսելների դինամիկ կառավարման հնարավորությունը և ավելի լավ ջերմային կառավարումը հնարավորություն են տալիս մտնել որոշ շատ հետաքրքիր բաների դեպքում: Մենք խոսում ենք օրինակ, սմարթ գրասենյակների մասին, որոնք հարմարվում են տարբեր լուսավորության պայմաններին՝ օրվա ընթացքում, կամ խանութներում այն հոլոգրաֆիկ դիսպլեների մասին, որոնք փոխվում են՝ կախված ապրանքների խրախուսման վրա: Ամեն ինչ ցույց է տալիս, որ COB տեխնոլոգիան ապագայի դիսպլեների նորարական տեխնոլոգիաների հիմք կդառնա:

COB LED դիսպլեների կիրառությունը կրիտիկական միջավայրերում

24/7 կառավարման սենյակներում և գործողական կենտրոններում արդյունավետությունը

COB LED ցուցադրիչները դարձել են ընտրելի տարբերակ այն վայրերում, որտեղ առավել կարեւոր է հուսալիությունը, ինչպիսիք են օդային երթեւեկության վերահսկման սենյակները եւ արտակարգ իրավիճակների հրամանատարական կենտրոնները: Այս ցուցադրիչները չունեն այն առկա լիցքավորման կետերը, որոնք սովորաբար ձախողվում են սովորական SMD LED- ների մոտ, ըստ արդյունաբերության 2025 թվականի զեկույցների: Դա նշանակում է, որ նրանք շարունակում են աշխատել, երբ ձախողումները խաթարում են կարեւոր գործողությունները եւ վտանգում են կյանքերը: Էկրանները հպարտանում են անհավատալիորեն բարձր բանաձեւով, մինչեւ P0.4մմ պիքսելներ, ինչը թույլ է տալիս անձնակազմին տեսնել բոլոր մանրամասները բարդ քարտեզավորման համակարգերի եւ անվտանգության տեսախցիկների տեսանյութերի մասին նույնիսկ այն բանից հետո, երբ նրանք ժամերով նայում են դրանց: Ցանկացած անձի համար, ով պետք է անընդհատ հետեւի ենթակառուցվածքների վիճակին, այս տեսողական հստակության մակարդակը մեծ տարբերություն է ստեղծում խնդիրները հայտնաբերելու համար, նախքան դրանք աղետի վերածվելը:

Փոխանակման օգտագործման դեպքեր. Բարձր պայծառություն, ցածր պահպանման կարիք ունեցող նշանային լուծումներ

Շատ խանութներ անցնում են COB LED էկրաններին, քանի որ դրանք ապահովում են հիանալի տեսանելիություն, նույնիսկ այն դեպքում, երբ արևը ուղղակի լույս է տալիս դրանց վրա, մինչդեռ գունային ճշգրտությունը մնում է մոտ 98%: Այդ էկրաններն ունեն հերմետիկ կառուցվածք, որը փոշուց պաշտպանում է ի հակադրություն այն թափանցիկ LED տարբերակներին, որոնք արագ կերպով փոշի են հավաքում մարդաշատ վայրերում: Ինչպե՞ս են այդ ամենը արդյունք տալիս. ըստ 2025 թվականի արդյունաբերական տվյալների, խանութները հայտնում են մոտ 30%-ով քիչ մաքրում պահանջող ծախսեր հինգ տարի հետո: Երկրի ամբողջ շուկաներում այժմ տեղադրում են այդպիսի էկրաններ նաև իրենց ինտերակտիվ տեղեկատուների համար: Այստեղ ջերմաստիճանի հետ մի հետաքրքիր բան է տեղի ունենում. մակերեսը մնում է մոտ 15 աստիճան Ցելսիուսով ավելի ցուրտ, քան սովորական LED-ները: Սա իրական տարբերություն է անում հաճախորդների համար, ովքեր գործարքների ժամանակ պետք է մատները էկրանին դնեն՝ առանց այրվելու կամ անհարմարություն զգալու:

Ինտելեկտուալ համակարգերի և IoT-ի հետ ինտեգրում ադապտիվ կառավարման համար

Նորագույն COB էկրանները այժմ առաջարկում են ներկառուցված IoT սենսորներ, որոնք կարող են կարգավորել պայծառությունը և հաստատունությունը՝ կախված շրջապատող լույսի քանակից: Սա իրականում նվազեցնում է էներգիայի սպառումը մոտ 25%-ով այն ճաշակով լցված խելացի գրասենյակներում, որոնք այսօր ամենուր ենք տեսնում: Երբ տեղադրվում են գնացքակայաններում կամ օդանավակայաններում, այս էկրանները միանում են AI-ով աջակցվող ցուցանակների հետ՝ ցույց տալով մարդկանց, թե իրական ժամանակում որտեղ են կուտակվում մարդաշփթությունները: COB տեխնոլոգիայի աշխատանքի և այս կարգավորվող հսկողությունների հետ համատեղելիությունը նշանակում է, որ տեղադրումները ավելի երկար են դիմանում նորոգման կարիք առաջանալուց: Բացի այդ, մեծամասամբ բարելավումներն իրականացվում են ծրագրային թարմացումների միջոցով՝ ամբողջ սարքաշինության փոխարինման փոխարեն, ինչը ժամանակի ընթացքում փոխհատուցում է գումարը և նվազեցնում է թափոնները:

Ինչպես ընտրել ճիշտ LED էկրան. թափանցիկ, SMD, թե՞ COB:

Ընտրությունը 📐📐📐📐📐📐📐📐📐📐📐📐📐📐📐📐📐📐📐📐 , SMD , և COB LED էկրաններ կախված է կիրառման հատուկ բնույթից և արդյունավետության առաջնահերթություններից: Թափանցիկ LED տեխնոլոգիան առավել հարմար է ճարտարապետական և մանրածախ վաճառքի տարածքներում, որտեղ բնական լույսի և տեսողական բաց տարածքի պահպանումը կարևոր է՝ հատկապես փողոցային ցուցափեղկերի կամ շենքերի ճակատների համար, որոնք միաժամանակ հնարավորություն են տալիս դինամիկ գովազդային հարթակներ ստեղծել:

COB և SMD LED-ների համեմատություն՝ արժեք, արդյունավետություն և երկարաժամկետ սպասարկում

COB-ն ավելի լավ նկարի համասեռություն է ապահովում և 60%-ով ավելի լավ ջերմացրիչ հատկություններ ունի SMD-ի համեմատ (LED Association 2023), որը երկարաժամկետ սպասարկման ծախսերը նվազեցնում է՝ չնայած սկզբնական ներդրումների բարձր արժեքին: SMD-ն ավելի տնտեսապես շահավետ լուծում է մեծ մասշտաբային տեղադրումների համար, ինչպիսիք են մարզադաշտերի էկրանները, որտեղ մոդուլային նորոգման հնարավորությունը և ցածր սկզբնական գները առավելագույն նշանակություն ունեն:

Ձեր LED էկրանի ներդրման մասշտաբավորումը և ապագայի համար պատրաստվածությունը

Այն տարածքներում, որտեղ անհրաժեշտ է արտակարգ բարձր հնարավոր հստակություն, ինչպիսին եթերաշրջանների ստուդիաներն են կամ կառավարման սենյակները, COB տեխնոլոգիան իր 1 մմ-ից ցածր պիքսելային քայլի շնորհիվ իսկապես առանձնանում է, երբ խոսքը վարագուրների մեծ հարթակների մասին է, առանց վիզուալ միջակայքերի վահանակների միջև: Ընդհակառակը, SMD-ն առաջարկում է մի բան ամբողջովին այլը՝ շատ ավելի մեծ ճկունություն, եթե մեկը ցանկանում է կորացնել էկրանը կամ տեղադրել անսովոր ձևի տարածքում, և այն ամեն իր համար բավականին լավ է աշխատում, նույնիսկ երբ պիքսելների միջև հեռավորությունը գերազանցում է 1.2 մմ-ն: Իսկ այն, թե ինչն է ավելի լավ երկարաժամկետ հեռանկարում, կախված է մի քանի գործոններից: COB-ն ավելի երկար է տևում և ամենօրյա կայուն արդյունքներ է տալիս, ինչը տրամաբանական է այն վայրերի համար, որտեղ պատկերի որակն ամենակարևորն է: Սակայն, եթե բյուջեն սահմանափակ է կամ ստեղծագործական ազատությունը կարևոր է, ապա SMD-ի կամ թափանցիկ էկրանների ընտրությունը հաճախ ավելի իմաստալից է լինում ինչպես ֆինանսական, այնպես էլ դիզայնի տեսանկյունից:

Հաճախ տրվող հարցեր

Ո՞րն է COB-ի և թափանցիկ LED էկրանների հիմնական տարբերությունը:

COB ցուցադրումները կենտրոնանում են գունային հետեւողականության եւ ամրության վրա, մինչդեռ թափանցիկ ցուցադրությունները շեշտում են տեսողական բացությունը եւ ինտեգրումը թվային բովանդակության առանց բնական լույսի արգելափակման:

Որտեղ է առավել արդյունավետ թափանցիկ LED տեխնոլոգիան:

Անթափանցիկ LED տեխնոլոգիան իդեալական է ճարտարապետական վայրերում, խանութների ցուցահանդեսներում եւ ցանկացած այլ կիրառման համար, որտեղ կարեւոր է պահպանել բնական լույսը թվային բովանդակություն ցուցադրելու ընթացքում:

Ինչպե՞ս է COB LED տեխնոլոգիան նպաստում էներգետիկ արդյունավետությանը:

COB տեխնոլոգիան օգտագործում է ջերմային կառավարման բարելավված համակարգեր եւ խելացի վարորդային շրջաններ՝ էլեկտրաէներգիայի սպառումը նվազեցնելու համար, ինչը խնայում է էներգիան ավանդական LED նախագծերի համեմատ: