Az LED kijelzők alapvető működési elve

Fénykibocsátás félvezető átmeneteken keresztül (az LED-ek fizikai alapjai)

Az LED-képernyők valami olyasmin keresztül hoznak létre fényt, amit elektroluminiszcenciának neveznek, és ez speciális félvezető anyagokon belül történik. Alapvetően, amikor az áram áthalad a dióda p-n átmeneti rétegén, az elektronok találkoznak az úgynevezett lyukakkal, és apró fényrészecskéket, ún. fotonokat bocsátanak ki. Ez azt jelenti, hogy közvetlenül saját maguk állítják elő a fényt, anélkül, hogy háttérfényre lenne szükségük, ami különbözik az LCD-k működésétől. Az is nagyon fontos, hogy milyen félvezető anyagot használnak. Például a gallium-arszenid alkotja azokat a világosvörös LED-eket, amelyeket mindenhol láthatunk. Az itteni hatásfok elég lenyűgöző, mivel a legtöbb energia nem melegként disszipálódik. A teljesítmény közel kilenc tizede látható fénnyé alakul, nem veszik el hő formájában. Ennek a hatékonyságnak köszönhetően a modern LED-kijelzők elképesztő fényességi szinteket érhetnek el, néha akár körülbelül 10 ezer nit skálán. Ez teszi a kijelzőket tökéletes megoldássá olyan helyekre, ahol sok környezeti fény van, például stadionok vagy bevásárlóközpontok külső reklámtábláira nappali órákban.

RGB alpixeles architektúra és dinamikus szkennelés teljes színű képalkotáshoz

Egyetlen pixel valójában három apró, egymáshoz közeli alpixelt tartalmaz – pirosat, zöldet és kéket. Amikor ezek az alpixelek külön-külön impulzusszélesség-modulációval vezéreltek, pusztán a fény keverésével több mint 16 millió különböző színkombinációt hozhatnak létre. A kijelzőtechnológia működése is eltér a régebbi módszerektől. Ahelyett, hogy az egész képernyőt egyszerre világítanák meg, soronként pásztázzák végig. Ez a megközelítés körülbelül 40%-kal takarékosabb fogyasztású a hagyományos statikus meghajtási technikákkal szemben. Mivel szemeink rövid ideig megtartják a képeket, ez a szkennelési technika sima vizuális élményt biztosít annak ellenére, hogy a képernyő részei nem világítanak egyszerre. Emellett lehetővé teszi a frissítési gyakoriság jelentős növelését, amely elérheti a 3840 Hz fölötti értékeket, jobb szürkeárnyalat-vezérlést 14 és 16 bit mélység között, valamint csökkenti az elektronikus alkatrészek hőterhelését, amelyek a kijelzőt meghajtják.

Moduláris Tervezés: Skálázhatóság, Görbület és Karbantarthatóság

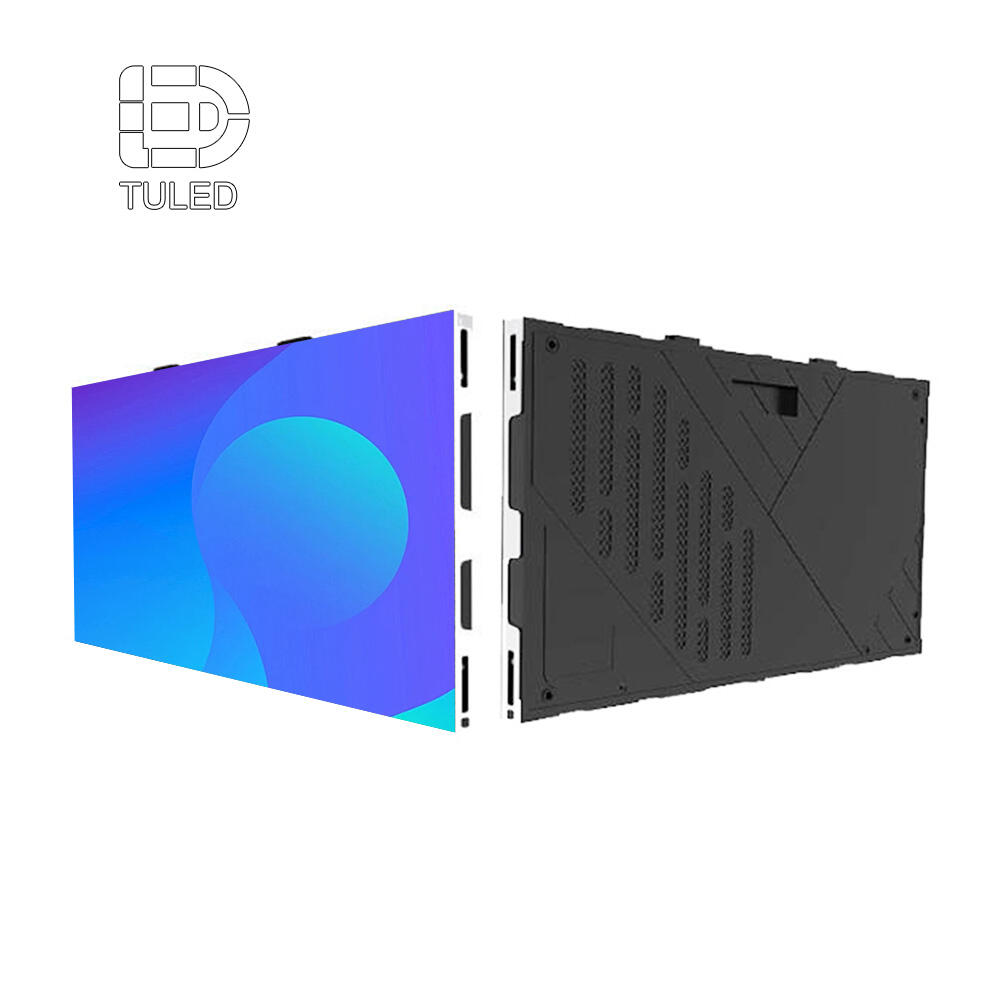

Melegcserélhető Modulok és Zökkenőmentes Csempézés Testreszabott Méretű LED Kijelzők Telepítéséhez

A moduláris LED kijelzők szabványos, egymásba kapcsolódó panelekből állnak, amelyek kis belső tereken használt tábláktól kezdve hatalmas stadionképernyőkig méretezhetők. A melegcserélhető moduloknak köszönhetően a technikusok hibás egységeket cserélhetnek ki anélkül, hogy a teljes kijelzőt ki kellene kapcsolni – ez különösen fontos olyan helyeken, ahol a leállás elfogadhatatlan, például TV-híradós stúdiókban vagy forgalmas vasútállomásokon. A legfrissebb piaci jelentések szerint ezeknek a moduláris rendszereknek a használata hosszú távon körülbelül 40 százalékkal csökkenti a karbantartási költségeket a hagyományos, egyszeri darabból álló kijelzőkhöz képest. A fejlett csempézési technológiának köszönhetően a panelek között többé nincsenek észrevehető hézagok. Ez konzisztens fényerőt és színeket eredményez akár szokatlan alakú elrendezéseknél, akár nagy íves felületeknél is. Kiskereskedelmi boltok, irányítóközpontok és koncertterek egyre inkább átvették ezt a technológiát, mivel az épület építészeti megoldásaiba illeszkedik, nem pedig úgy hat, mintha utólagos gondolat lenne.

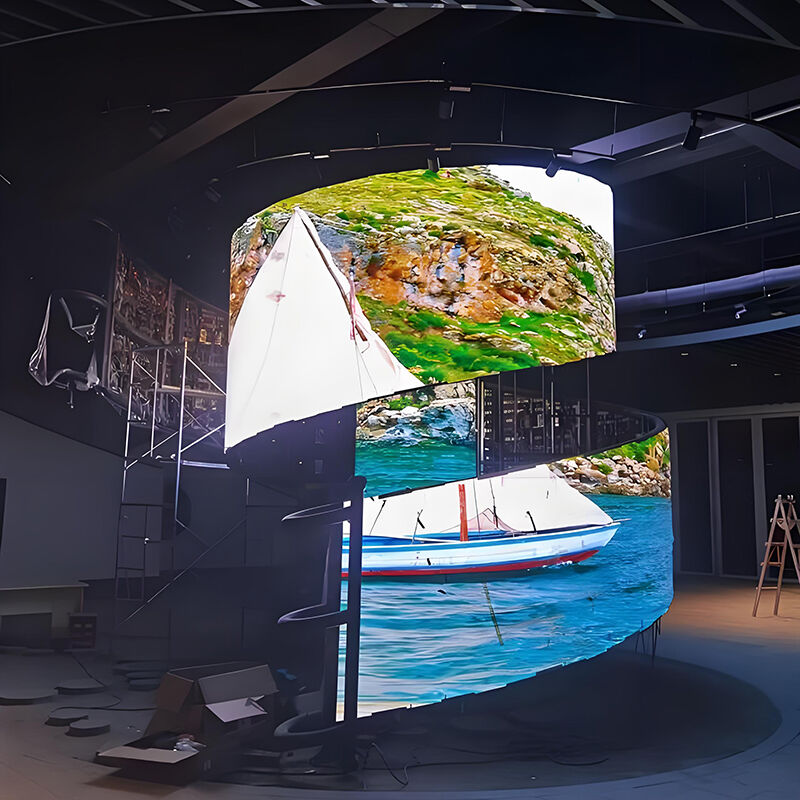

Görbült és lapos moduláris tömbök: kompromisszumok a szerkezeti integritás, a nézési szög és a karbantartás terén

A görbült LED kijelzők immertívebb élményt nyújtanak, és kiterjesztik azt a területet, ahol a nézők jó képminőséget kapnak, így különösen hasznosak nagy létesítményekben, például sportarénákban és koncerttermekben. Ezek a görbült elrendezések körülbelül 30%-kal csökkentik az éltorzítást, de van egy buktató. A görbült szerkezetek működéséhez speciálisan tervezett keretekre, testreszabott rögzítési megoldásokra és a beállítási folyamat során gondos kalibrációra van szükség. Mindez többletidőt és technikai bonyolultságot jelent a szokványos telepítésekhez képest. Másrészről a sík moduláris LED panelek egyszerűbb szerkezettel készülnek, amelyek könnyen igazodnak egymáshoz, és karbantartásuk is kevés gondot okoz. Bár ezek nem fedik le ugyanolyan széles látószöget optimális nézési minőségben, a 2023-as AV Integration Journal tanulmányai szerint átlagosan 25%-kal gyorsabbak a javítások ezen a sík rendszeren. Olyan helyeken, ahol a folyamatos üzem a legfontosabb, és a leállás pénzbe kerül, a sík változat gyakran ésszerűbb választás, annak ellenére, hogy a „legjobb” látószög keskenyebb. Amikor döntést hoznak a lehetőségek között, az üzemeltetőknek mérlegelniük kell, hogy valójában mennyire fontos a tágabb látómező a rejtett költségekkel szemben, beleértve a kezdeti telepítési kiadásokat, a folyamatos karbantartást és a végül szükségessé váló cseréket.

Rugalmas LED kijelző költségstruktúra: Fő árképzési tényezők

Prémium alkatrészek: Hajlítható nyomtatott áramköri lapok, megerősített rögzítőkeretek és rugalmas kábelek

Ahhoz, hogy jól teljesítsenek ismételt hajlítás közben, a hajlékony LED-kijelzők speciális anyagokra szorulnak, amelyek képesek elviselni az intenzív mozgást. A használt NYÁK-lemezek nem a szokványos FR-4 üvegszálas típusúak, hanem poliimidból vagy más hajlékony polimerekből készülnek. Ez a változtatás nyilvánvalóan bonyolultabbá teszi a gyártási folyamatot, az iparágban dolgozók szerint körülbelül 30–40 százalékkal növeli a munkamennyiséget. A szerkezeti tartás érdekében merevített alumíniumkereteket alkalmaznak beépített feszítőrendszerekkel, amelyek megakadályozzák a lehajlást vagy torzulást görbítés közben. Emellett olyan áramellátó és adatkábeleket használnak, amelyek ezerszeri hajlítás után sem törik el. Mindezek az alkatrészek együttesen majdnem a felét teszik ki annak a költségnek, ami egy prémium minőségű hajlékony kijelzőrendszer előállításába kerül, ami magyarázza, miért járnak magas árcédulával ezek a megoldások.

Kritikus költségtényezők: Képernyőméret, pixeltávolság, fényerő (nits), IP védettség és a telepítés bonyolultsága

Öt egymással összefüggő tényező határozza meg a végső árakat az alkatrész-választáson túl:

- Képernyő Mérete : A költségek nem lineárisan növekednek – nagyobb kijelzőkhöz több modul, nehezebb tartószerkezet és fejlettebb hőkezelés szükséges.

- Pixel távolság : A finomabb pitch-ek (pl. P1.5–P2.5) magasabb felbontást nyújtanak, de szigorúbb gyártási tűréseket és sűrűbb LED-elhelyezést igényelnek – ára kb. 60%-kal magasabb, mint a durvább változatoké (P4–P10).

- Fényerő : Kültéri vagy napfényes környezetben használt, 6000 nits fényerőt igénylő alkalmazásoknál speciális hőtervezés szükséges, beleértve réz hűtőbordákat és aktív hűtést – ami anyagilag és mérnöki szempontból is drágább.

- IP besorolás : Az időjárás- és porálló házak (IP65/IP68) tömítéseket, zárt csatlakozókat és konform bevonatokat tartalmaznak, amelyek az alapárát 15–25%-kal növelik.

- Telepítési bonyolultság : Gömbölyű, homorú vagy szabad formájú konfigurációk egyedi rögzítést, lézeres igazítást és helyszíni kalibrációt igényelnek – a lapos falas telepítésekhez képest 30–50%-kal több munkaórát igényelnek.

Egyedi építészeti projektek esetén a beszerzési lánc elemzései azt mutatják, hogy a telepítés, üzembe helyezés és műszaki támogatás rendszerint a teljes projekt költségvetésének több mint 35%-át teszi ki – hangsúlyozva a tervezők, integrátorok és kijelzőgyártók közötti korai együttműködés fontosságát.

GYIK

Mi különbözteti meg az LED-kijelzőket az LCD-kétől?

Az LED-kijelzők közvetlenül hozzák létre a fényt elektroluminescencián keresztül, nem szükséges nekik háttérfény, ellentétben az LCD-kkel, amelyek háttérfényt igényelnek a képernyő megvilágításához.

Hogyan javítja az RGB alpixeles architektúra az LED-kijelzők minőségét?

Az RGB alpixeles architektúra több mint 16 millió színkombinációt tesz lehetővé a piros, zöld és kék alpixelek független szabályozásával, így kiváló minőségű, élénk képet eredményezve.

Milyen előnyei vannak a moduláris LED-kijelzőknek?

A moduláris LED-kijelzők skálázhatóságot, zökkenőmentes integrációt és könnyű karbantartást kínálnak a melegcsere-ba cserélhető modulok és a fejlett csempézési technológia miatt.

Hogyan viszonyulnak az ívelt LED-kijelzők a sík kijelzőkhöz?

A görbült LED kijelzők szélesebb látószögű, immerszívabb élményt nyújtanak, de összetettebb telepítést igényelnek, mint a sík kijelzők.

Milyen tényezők befolyásolják a rugalmas LED kijelzők árát?

Az árat a képernyő mérete, a pixeltávolság, a fényerő, az IP besorolás és a telepítés összetettsége határozza meg, további szerepet játszanak a prémium alkatrészek, például a hajlítható nyomtatott áramkörök is.